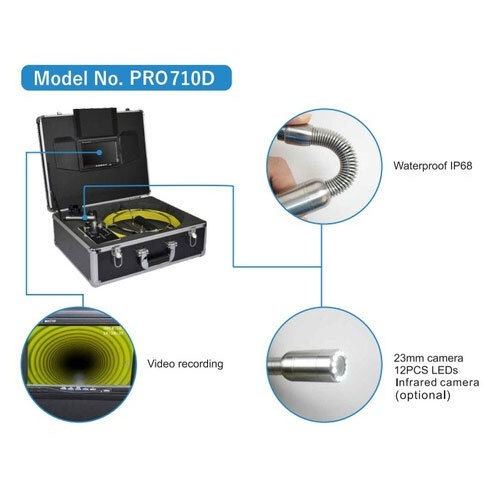

Drain And Pipe (PRO710D)

Product Details:

- Usage Industrial

- Power 12 Volt (v)

- Size 23 mm X 120 mm

- Operating Mode Automatic

- Product Type Drain And Pipe (PRO710D)

- Color Black

- Click to View more

Drain And Pipe (PRO710D) Price And Quantity

- 1 Piece

Drain And Pipe (PRO710D) Product Specifications

- 12 Volt (v)

- Black

- Industrial

- 23 mm X 120 mm

- Automatic

- Drain And Pipe (PRO710D)

Drain And Pipe (PRO710D) Trade Information

- 7-10 Days

Product Description

Product Specification:

Camera Head

| Camera size | 23 mm x 120 mm |

| Sensor size | 1/4 inch |

| View angle | 120 deg |

| Work current | 100 MA |

| Power supply | DC 12V |

| Camera light | 12 pcs white Leds |

| Resolution | Pal: 720 x 576 NTSC: 720 x 480 |

| Glass material | Sapphie glass |

| Shell material | Stainless steel |

Cable Wheel

| Cable size | 320 mm x 110 (h) |

| Wire material | Fiberglass rod |

| Wire length | 20 m (standard) |

| Wire diameter | 5.0 mm |

Skid

| Skid 1 | 40 mm |

| Skid 2 | 80 mm |

Monitor

| Size | 7 inch digital color |

| Total pixels | 800 x 480 |

| Work current / supply | 250 MA/ DC 12 V |

| OSD language | English |

| Image reversible |

|

| Model | 16:9 and 4:3 |

| Sunshade |

|

Li-ion Battery

| Total power | 14w |

| Charge time | 5 hours |

| Work time | >260 minutes |

Suit case

| Size | L 480 x W 415 x H 200 mm |

| Material | Fire board and aluminum alloy |

Control Box

| Work current / supply | 150 MA/ DC 12 V |

| Storage medium | 8G SD card (max 32 G) SD card reader |

| Battery level display |

|

| Picture snap and movie record |

|

| DVR total pixels | 720 x 576 (D1) |

| Movie format | AVI |

| Microphone audio record |

|

| Stereo earphone output |

|

Charger

| Input | AC 100 240 V 50/60 HZ |

| Output | DC 12V/ 1000MA |

| DC plug diameter | 2.1 mm |

Advanced Industrial Solution

PRO710D Drain and Pipe is designed to meet the rigorous demands of industrial environments. Its automatic operating mode streamlines maintenance and helps prevent clogging and overflow, ensuring smoother drain operations. The devices high durability and corrosion-resistant black finish contribute to its long service life in industrial setups.

Compact and Efficient Design

Measuring just 23 mm by 120 mm, this product offers a compact footprint without compromising capacity or functionality. Its 12-volt operation makes it compatible with standard industrial power sources, and the automatic features reduce the need for manual intervention, optimizing operational efficiency.

FAQs of Drain And Pipe (PRO710D):

Q: How does the PRO710D Drain and Pipe operate automatically in industrial environments?

A: The PRO710D uses automatic sensors or timers to detect water flow or blockages, activating the drainage mechanism as needed. This minimizes manual oversight and maintains continuous operation in demanding industrial settings.Q: What are the main benefits of using the PRO710D Drain and Pipe in industrial applications?

A: It offers efficient wastewater management, reduced maintenance requirements, and long-lasting durability due to its robust construction and corrosion-resistant black finish. Its automatic operation decreases downtime and ensures reliable performance.Q: When should the PRO710D Drain and Pipe be installed in an industrial facility?

A: Installation is ideal during the setup or upgrade of drainage infrastructure or when existing systems require modernization. Its compact size allows for easy integration in new and existing setups.Q: Where can the PRO710D Drain and Pipe be utilized most effectively?

A: This product is best suited for industrial drainage systems, wastewater treatment plants, and areas prone to frequent or heavy water flow, where reliable automatic drainage is essential.Q: What is the process for installing the PRO710D Drain and Pipe?

A: Installation involves positioning the unit within the designated drainage pathway, connecting it to a 12-volt power supply, and configuring its automatic controls according to site requirements, typically carried out by a qualified technician.Q: How does the compact size of the PRO710D Drain and Pipe benefit industrial users?

A: Its 23 mm x 120 mm dimensions make it suitable for installations in tight spaces while still providing ample drainage capacity. This allows industrial facilities to maximize available space without sacrificing performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free