Ultrasonic Thickness Measurement Services

Product Details:

- Temperature -20 - 250 Celsius (oC)

- Resolution 0.01 mm

- Number of Specimens Multiple, as per requirement

- Measuring Range 0.5 mm 500 mm

- Accuracy 0.1 mm or better

- Product Type Ultrasonic Thickness Measurement Services

- Material Steel

- Click to View more

Ultrasonic Thickness Measurement Services Price And Quantity

- 1 Piece

Ultrasonic Thickness Measurement Services Product Specifications

- Customizable as per component

- 1 cm minimum area

- Steel

- Manual/Semi-automatic

- Digital LCD

- Industrial

- 095% RH (non-condensing)

- USB/Bluetooth

- 3.6V 7.2V DC or 220V AC

- 0.01 mm

- -20 - 250 Celsius (oC)

- Multiple, as per requirement

- 0.5 mm 500 mm

- Up to 500 mm depending on probe

- Ultrasonic Thickness Measurement Services

- 0.1 mm or better

- Thickness measurement of metals, pipes, tanks, and structures

- Ultrasonic Thickness Gauge

- Rechargeable Battery or 220V AC

- 2 MHz 10 MHz (probe dependent)

- Handheld or Probe Mount

- Adjustable, Up to 50 mm/sec

- Instantaneous (<1s)

- Manual / Auto

- For use on steel, iron, and alloys

- Portable, Typically <3 kg

- Up to 500 measurements per hour

- Non-destructive, portable, real-time data logging, backlight display, auto-calibration

- Standard probe port, multiple sizes available

- 0.5 mm 500 mm (steel)

Ultrasonic Thickness Measurement Services Trade Information

- 100 Piece Per Week

- 1 Week

Product Description

To verify that global and local vessel strength is preserved, Ultrasonic Thickness Measurement Service is done. inspect the state of the vessel, and determine how much material remains. Discover all conceivable areas of concern when it comes to measuring thickness and account for the specifics of every type of vessel. To acquire thickness measurements, the vessel must be either pre-docked or dry-docked, and the measurements are done by certified inspectors. The ability to research, understand, and then communicate correct and up-to-date information on repairs and maintenance in order to aid in design and budgeting. We use highly experienced and well-qualified specialists that can perform in a wide range of different roles, such as: steel supervision, pre-buy inspection, visual inspection, and photo reporting for rendering fulfilling Ultrasonic Thickness Measurement Service.

Leveraging on the vast domain expertise, we are engaged in trading and exporting Ultrasonic Thickness Measurement Services.

| Duration | 1-3 Days |

| Place Of Testing | Field |

| Location | Mumbai, Maharashtra |

| Temperature Range | -20 - 250 Deg |

| Accuracy | 0.1% |

| Material | Steel |

Reliable Measurement Across Conditions

This service is engineered to deliver accurate thickness readings on metalseven when surfaces are painted, corroded, or coated. Our customized probes and sophisticated alarm features help detect wall loss or corrosion before it becomes critical, ensuring the long-term safety and integrity of industrial assets.

Portable and Versatile for Any Site

Lightweight and highly portable (<3 kg), our equipment allows rapid deployment in the field or workshop. The rechargeable battery and robust design enable seamless operation in varied environments, from high-humidity zones (up to 95% RH) to extreme temperature ranges (-20C to 250C), making it ideal for a broad spectrum of industrial applications.

Comprehensive Data Management and Reporting

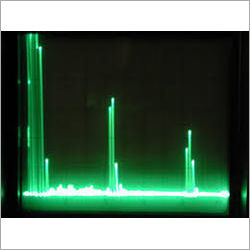

With internal memory for up to 50,000 readings, real-time logging, and intuitive digital output, our service simplifies record-keeping and analysis. Clients receive both digital and printed reports with clear graphical representations, supporting compliance, maintenance planning, and audit requirements.

FAQs of Ultrasonic Thickness Measurement Services:

Q: How does ultrasonic thickness measurement work on painted or coated steel surfaces?

A: Our advanced ultrasonic probes transmit sound waves through coatings, paint, or corrosion, reflecting from the steel substrate to provide accurate thickness readings. This non-destructive method eliminates the need to remove surface layers, ensuring fast and reliable inspection.Q: What is the typical process followed for onsite ultrasonic thickness measurement?

A: Upon arrival, our technician calibrates the device using standard calibration blocks, selects the appropriate probe, and sets user-defined parameters. The portable gauge is then applied to clean or as-is surfaces. Measurements are immediately displayed and logged, and a detailed digital and printed report is generated post-inspection.Q: Where can these ultrasonic thickness measurement services be used?

A: Our services are suitable for various industrial settings, including factories, refineries, storage tank farms, pipelines, and workshopsanywhere steel structures or components require thickness monitoring or corrosion assessment.Q: What are the benefits of using this service for industrial applications?

A: Key benefits include fast, accurate, and non-destructive thickness measurement, suitability for painted or corroded surfaces, instant data access, detailed reporting, and minimal operational downtime. The service helps maintain asset integrity, reduce inspection times, and support regulatory compliance.Q: When should ultrasonic thickness testing be conducted?

A: Ultrasonic thickness testing should be scheduled as part of regular maintenance, after visible signs of corrosion, following repairs, or before asset certification and audits to ensure ongoing safety and compliance with industry standards.Q: What types of data reports are provided after measurement?

A: Clients receive comprehensive reports in both digital and printed formats, featuring graphical representations of thickness profiles, measurement summaries, and detailed data logs. These reports facilitate easy interpretation and documentation for internal records and regulatory review.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free