Positive Material Identification

Product Details:

- Usage Industrial

- Material Metal

- Dimension (L*W*H) Standard / Custom

- Product Type Positive Material Identification

- Power Standard

- Voltage Standard

- Color Black

- Click to View more

Positive Material Identification Price And Quantity

- 115000.00 INR/Unit

- 1 Unit

Positive Material Identification Product Specifications

- Industrial

- Metal

- Black

- Standard

- Standard / Custom

- 50-60 Hertz (HZ)

- Ambient

- Positive Material Identification

- Standard

Positive Material Identification Trade Information

- 1000 Unit Per Day

- 1 Week

Product Description

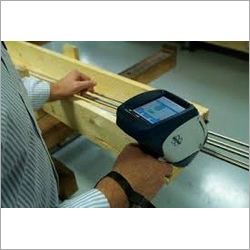

We have carved a niche in the market as a prime organization engaged in offering Positive Material Identification.We conduct non-destructive testing method to verify that supplied materials conform to the proper standards and specifications. Our on-site inspection and testing team uses highly sophisticated handheld and portable X-Ray florescence and optical emission spectrometer for the testing purposes. Through Positive Material Identification we provide quick results for product verification and sorting of product.

Features of Positive Material Identification:

- Highly specific and accurate results

- Field testing with laboratory quality

- Quick results for product verification

Product details of Positive Material Identification:

| Location | Mumbai, Maharashtra |

| Sample Test Location | In Laboratory |

| Industry Type | Refineries |

| Application Type | Material Sorting |

| Material Type | Metal |

| Testing Type | Positive Material Identification |

Comprehensive Alloy Verification

With our PMI solutions, industrial users achieve reliable alloy verification and chemical composition analysis directly on-site. The blend of handheld and stationary devices empowers quality checks across manufacturing, maintenance, and asset management processes, delivering digital data with each test.

Advanced Testing Technology

Employing cutting-edge X-Ray Fluorescence (XRF) and Optical Emission Spectroscopy (OES), our instruments deliver high precision in identifying metal constituents. These techniques enable rapid measurement, minimizing downtime and supporting compliance with industry standards.

Compliance and Customization

Our instruments adhere strictly to ASTM E 1476 guidelines, supporting both standard and custom dimensions to fit specific operational requirements. Designed in black color for durability and aesthetics, they operate within ambient temperatures and standard power setups for consistent performance in industrial settings.

FAQs of Positive Material Identification:

Q: How does Positive Material Identification (PMI) verify metal alloys on-site?

A: PMI leverages X-Ray Fluorescence (XRF) and Optical Emission Spectroscopy (OES) technologies to analyze the chemical composition of metallic samples, enabling accurate onsite verification of alloy types without necessitating laboratory testing.Q: What types of results can I expect from PMI devices?

A: PMI instruments provide high-precision, immediate data, displayed directly on the screen and outputted as digital reports. These results identify alloy constituents and confirm compliance with ASTM E 1476 standards.Q: When should PMI testing be performed in an industrial setting?

A: PMI is ideally conducted during material receipt, fabrication, maintenance, or prior to the installation of assets to ensure the correct composition and integrity of metals used in production or critical structures.Q: Where are PMI solutions commonly used?

A: PMI is most frequently utilized in industrial environments such as manufacturing plants, refineries, and construction sites where precise metal identification is essential for quality assurance and regulatory compliance.Q: What is the process of using PMI equipment?

A: To operate PMI equipment, users simply position the handheld or stationary device on the metal surface and initiate analysis. In seconds, the instrument assesses and displays element composition, generating a digital report for documentation.Q: How does portable PMI equipment benefit industrial users?

A: Handheld and stationary PMI models provide flexibility and mobile convenience, allowing users to conduct material verification at multiple locations quickly and efficiently without disrupting ongoing operations.Q: What standards do these PMI solutions meet, and why is compliance important?

A: Our PMI instruments conform to ASTM E 1476, ensuring reliable and standardized testing practices. Adhering to recognized standards builds confidence in material quality and supports regulatory and safety protocols.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free