Drain and Pipe (PRO710D5)

Product Details:

- Usage Industrial

- Power Battery

- Function Drainage and Pipe Flow

- Product Type Drain and Pipe (PRO710D5)

- Operating Mode Automatic

- Color Black

- Click to View more

Drain and Pipe (PRO710D5) Price And Quantity

- 1 Piece

Drain and Pipe (PRO710D5) Product Specifications

- Black

- Drain and Pipe (PRO710D5)

- Drainage and Pipe Flow

- Automatic

- Industrial

- Battery

Drain and Pipe (PRO710D5) Trade Information

- 7-10 Days

Product Description

Product Specification:

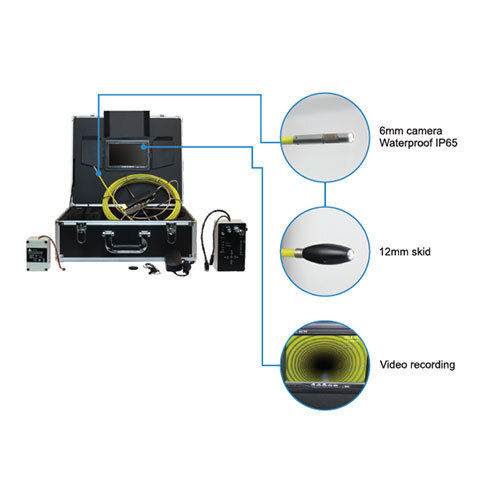

Camera Head

| Camera size | 6 mm |

| View angle | 60 deg |

| Work current | 150 MA |

| Power supply | DC 3.3 V |

| Camera ligh | 4 pcs white Leds |

| Resolution | Pal: 720 x 625 NTSC: 720 x 525 |

| Glass material | Stainless steel |

| Shell material | Stainless steel |

Cable Wheel

| Cable size | 320mm x 110 (h) |

| Wire material | Fiberglass rod |

| Wire length | 20 m (standard) |

| Wire diameter | 5.0 mm |

Skid

| Skid | 12 mm |

Monitor

| Size | 7 inch digital color |

| Total pixels | 800 x 480 |

| Work current / supply | 150 MA/ DC 12 V |

| OSD language | English |

| Image reversibile |

|

| Model | 16:9 and 4:3 |

| Sunshade |

|

Li-ion Battery

| Total power | 14w |

| Charge time | 5 hours |

| Protective voltage | 8.1 V |

| Work time | >260 minutes |

Suit case

| Size | L 480 x W 415 x H 200 mm |

| Materail | Fire board and aluminum alloy |

Control Box

| Work current / supply | 150 MA/ DC 12 V |

| Storage medium | 8G SD card (max 32 G) SD card reader |

| Battery level dispaly |

|

| Picture snap and movie record |

|

| DVR total pixels | 720 x 576 (D1) |

| Movie format | AVI |

| Microphone audio record |

|

| Stereo earphone output |

|

Charger

| Input | AC 100 240 V 50/60 HZ |

| Output | DC 12V/ 1000MA |

| DC plug diameter | 2.1 mm |

Superior Durability and Performance

Manufactured from high-strength polymer, the PRO710D5 drain and pipe system delivers exceptional resilience against chemicals and corrosion. Its advanced engineering allows for reliable operations at temperatures up to 80C, making it a dependable choice for demanding industrial applications.

Versatile and Easy Installation

The slip fit/push fit connection type facilitates simple, hassle-free installation with no requirement for welding expertise or tools. With customizable section lengths, the system adapts to varied industrial layouts and is designed to deliver seamless performance for drainage and pipe flow.

FAQs of Drain and Pipe (PRO710D5):

Q: How is the PRO710D5 drain and pipe installed in industrial settings?

A: The PRO710D5 utilizes a slip fit/push fit connection, allowing for quick and easy assembly without the need for welding. Simply align and connect the sections by hand, which streamlines installation even in restricted industrial spaces.Q: What are the primary benefits of using a high-strength polymer for this drainage system?

A: High-strength polymer ensures the pipe is lightweight yet extremely durable, providing excellent resistance to corrosion and a wide array of chemicals. This material also supports temperature resistance up to 80C, promoting long service life and low maintenance needs.Q: When should I consider using the PRO710D5 in my facility?

A: This system is ideal for industrial environments where reliable, corrosion-resistant, and easy-to-maintain drainage and pipe flow solutions are required, particularly in scenarios demanding high temperature and chemical resilience.Q: Where can the PRO710D5 drain and pipe system be deployed?

A: The PRO710D5 is suitable for a wide range of industrial drainage applications, including manufacturing plants, chemical processing units, and facilities where exposure to harsh substances is common.Q: What is the process for customizing pipe length for this product?

A: We offer pipe sections in customizable lengths based on the specific requirements of your installation. Simply provide your precise dimensions when placing the order, and we will manufacture the sections accordingly.Q: How does the automatic operating mode enhance the systems usage?

A: The automatic operation, coupled with battery power, allows for consistent drainage and pipe flow management with minimal manual intervention, enhancing workflow efficiency in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free