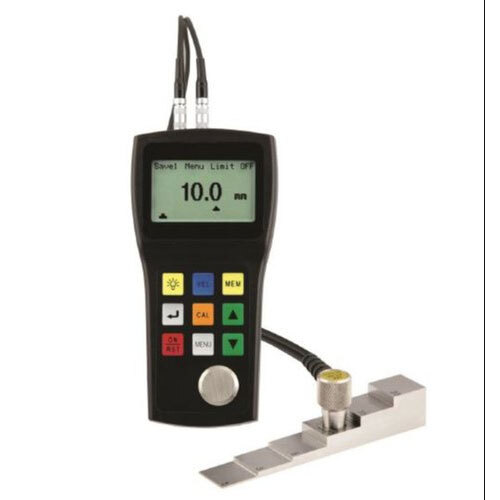

High Precision Ultrasonic Thickness Gauge

Product Details:

- Display FSTN digital LCD with cold back light inch/mm

- Usage Industrial

- Size 132 X 76.2 mm

- Material Plastic

- Product Type High Precision Ultrasonic Thickness Gauge

- Weight 323 Grams (g)

- Color Black

- Click to View more

X

High Precision Ultrasonic Thickness Gauge Price And Quantity

- 1 Piece

High Precision Ultrasonic Thickness Gauge Product Specifications

- Plastic

- 323 Grams (g)

- Industrial

- High Precision Ultrasonic Thickness Gauge

- 132 X 76.2 mm

- FSTN digital LCD with cold back light inch/mm

- Black

High Precision Ultrasonic Thickness Gauge Trade Information

- 7-10 Days

Product Description

A high precision ultrasonic thickness gauge is a specialized instrument used to measure the thickness of various materials by employing ultrasonic waves. These gauges are commonly used in industries such as manufacturing, aerospace, automotive, and construction, where precise measurements of material thickness are essential for quality control and safety purposes.

Key features of a high precision ultrasonic thickness gauge typically include:

2. High Accuracy: These gauges offer high levels of accuracy, often with measurements down to fractions of a millimeter or even micrometers, depending on the model and application.

3. Multiple Measurement Modes: They often support various measurement modes to accommodate different materials and surface conditions, such as pulse-echo mode and echo-echo mode.

4. Wide Range of Applications: These gauges are versatile and can measure the thickness of a wide range of materials including metals, plastics, glass, composites, and ceramics.

5. Digital Display: Most modern ultrasonic thickness gauges feature digital displays that provide clear and easy-to-read measurements.

6. Data Logging and Connectivity: Some advanced models offer data logging capabilities, allowing users to store and analyze measurement data. They may also have connectivity options such as USB or Bluetooth for transferring data to a computer or other devices.

7. Durable Construction: Since these gauges are often used in demanding industrial environments, they are typically built to be rugged and durable, with features like shock resistance and waterproofing.

8. User-Friendly Interface: They typically have intuitive user interfaces with easy-to-navigate menus and settings, making them accessible to operators with varying levels of experience.

9. Calibration Options: Calibration is critical for maintaining accuracy. High precision ultrasonic thickness gauges often provide calibration options to ensure accurate measurements over time.

10. Battery Operation: Many models are battery-powered for portability and convenience, although some may also have options for AC power.

11. Compliance with Standards: Depending on the industry and application, these gauges may need to comply with specific standards and regulations, such as ASTM or ISO standards.

Uses of High Precision Ultrasonic Thickness Gauge:

1. Manufacturing Quality Control: In manufacturing industries such as automotive, aerospace, and electronics, these gauges are used to ensure the consistency and quality of materials during production processes. They help detect variations in thickness that may affect the performance or integrity of finished products.

2. Metal Fabrication and Welding: Ultrasonic thickness gauges are essential tools for metal fabricators and welders to monitor the thickness of metal plates, pipes, and structures. They ensure that welds meet specified thickness requirements and detect any defects or inconsistencies in the welded joints.

3. Corrosion Monitoring and Maintenance: Industries like oil and gas, marine, and infrastructure maintenance use ultrasonic thickness gauges to monitor the thickness of metal structures over time. By regularly measuring thickness, they can detect corrosion, erosion, or material degradation, allowing for timely maintenance and repair to prevent structural failures.

4. Pipeline Inspection: Ultrasonic thickness gauges are employed in the inspection of pipelines for oil, gas, water, and other fluids. They help identify areas of thinning due to corrosion, erosion, or other factors, enabling operators to prioritize maintenance and prevent leaks or ruptures.

5. Shipbuilding and Maritime Industries: Shipbuilders and maritime maintenance teams use ultrasonic thickness gauges to assess the thickness of ship hulls, bulkheads, and other structural components. Regular inspections help ensure vessel integrity and compliance with maritime safety regulations.

6. Construction and Civil Engineering: In construction projects involving concrete, ultrasonic thickness gauges are used to measure the thickness of concrete slabs, walls, and structural elements. This helps verify construction quality and ensure adherence to design specifications.

7. Material Testing and Research: Ultrasonic thickness gauges are valuable tools in material testing laboratories and research facilities. Researchers use them to characterize the mechanical properties of materials and study the effects of various factors such as temperature, pressure, and stress on material thickness.

8. Safety Inspections and Non-Destructive Testing (NDT): Ultrasonic thickness gauges are widely used in non-destructive testing (NDT) to assess the integrity of structural components without causing damage. They play a crucial role in safety inspections of critical infrastructure, industrial equipment, and transportation systems.

9. Agriculture and Food Processing: In agriculture and food processing industries, ultrasonic thickness gauges are utilized to measure the thickness of materials such as plastic films, packaging materials, and food containers. This helps ensure product quality and compliance with safety standards.

Precision and Reliability for Industrial Measurement

Engineered for industrial use, this Ultrasonic Thickness Gauge provides accurate measurements essential for quality control and maintenance. Its advanced FSTN LCD display with a cold backlight ensures clarity even in dim environments. Lightweight and ergonomically designed, the device streamlines operations for professionals who value precision and durability in their industrial tools.

Effortless Operation and Versatile Applications

Switch between inch and millimeter readings to accommodate various project requirements. With a simple interface and reliable ultrasonic technology, the gauge is suited for non-destructive testing of plastics, metals, and more, aiding in asset maintenance, manufacturing quality checks, and material conformity assessments.

FAQs of High Precision Ultrasonic Thickness Gauge:

Q: How does the High Precision Ultrasonic Thickness Gauge measure material thickness?

A: This gauge uses ultrasonic waves to determine the thickness of materials non-destructively. It emits ultrasonic pulses through the material and calculates thickness based on the time it takes for the pulse to return, ensuring precise readings without causing any harm to the tested item.Q: What advantages does the FSTN digital LCD with cold backlight offer?

A: The FSTN digital LCD equipped with cold backlight provides high visibility and improved contrast, allowing users to easily read measurements in both low-light and bright environments, which is especially beneficial for industrial settings.Q: Where can this ultrasonic thickness gauge be effectively used?

A: This device is ideal for use in a variety of industrial sectors such as manufacturing, export, service provision, supply chain, and trading, particularly within India. Its versatility allows it to check thickness in pipes, tanks, structural components, and more.Q: When should I use the inch/mm conversion feature on the device?

A: You can utilize the inch/mm conversion to suit project-specific requirements or to comply with international standards. This flexibility is particularly helpful when working with clients or partners using different measurement systems.Q: What is the process for operating the ultrasonic thickness gauge?

A: Begin by placing the probe on the materials surface, ensuring good contact. The device sends an ultrasonic pulse through the material; the time taken for the echo to return is processed and displayed as the materials thickness either in inches or millimeters.Q: How durable is the device for industrial usage?

A: Built from sturdy black plastic, the gauge is designed to withstand rigorous industrial environments while remaining lightweight (323 grams) and portable, making it suitable for regular use in demanding workspaces.Q: What are the main benefits of using this thickness gauge for exporters and manufacturers?

A: Exporters and manufacturers benefit from improved quality control, compliance with industry standards, and efficient inspection processes, thanks to the gauges high precision readings and user-friendly functionality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese