Magnetic Particle Inspection Services

Product Details:

X

Magnetic Particle Inspection Services Price And Quantity

- 1 Piece

Magnetic Particle Inspection Services Trade Information

- 100 Piece Per Week

- 7-10 Days

Product Description

Magnetic Particle Inspection Services details

| Service Type | Magnetic Particle Inspection Services |

| Magnetic Type | Direct Magnetization Services |

| Inspection Service For | Production Discontinuities |

| Inspection Method | Specific Instrumentation |

| Usage/Application | Industrial |

| Mode Of Report | Soft Copy, Hard Copy |

Comprehensive Magnetic Particle Testing

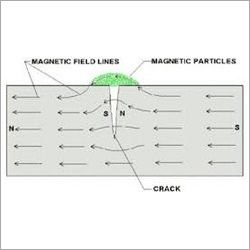

We utilize advanced magnetic particle techniquesboth wet and dryfor precise surface and slightly subsurface defect detection. Our expertise includes handling components of various sizes and configurations, ensuring thorough inspection regardless of complexity or scale.

Certified Personnel and Global Standards

All inspections are conducted by ASNT Level II or III certified professionals who strictly adhere to ASTM E1444 and IS 6410 standards. Detailed inspection reports with clear findings are delivered to ensure full traceability and meet industry compliance requirements.

Flexible and Scalable Service Delivery

Our MPI services are available onsite at your facility or at our in-house testing centers, catering to both small and large batches. We manage components up to 5 tons and provide certifications and documentation per customer requirements, ensuring a smooth and efficient process.

FAQs of Magnetic Particle Inspection Services:

Q: How is Magnetic Particle Inspection performed for different component sizes and shapes?

A: Magnetic Particle Inspection is adaptable to various component geometries by using different magnetization methods such as yoke, coil, prod, or central conductor techniques. This ensures optimal inspection coverage whether assessing individual parts or an entire assembly.Q: What types of defects can be detected using your MPI services?

A: Our services can identify surface and slightly subsurface flawsincluding cracks, porosity, seams, and lapsin ferromagnetic materials. The combination of wet and dry particle media ensures high sensitivity and reliability in flaw detection.Q: When should Magnetic Particle Inspection be used in my industry?

A: MPI is best utilized during regular maintenance, prior to component commissioning, or after suspected overloading in industries such as automotive, aerospace, construction, oil & gas, and power generation to ensure critical component integrity.Q: Where can I access your Magnetic Particle Inspection services?

A: You can engage our inspection teams for either onsite evaluations at your premises anywhere in India or opt for in-house services at our well-equipped testing facilities, depending on your operational requirements.Q: What is the typical process and duration for an MPI job?

A: The process involves surface preparation, magnetization of the component, application of test media, visual inspection, and detailed reporting. Service duration varies with component size and quantity, and we accommodate both urgent and scheduled inspections.Q: What are the benefits of choosing your certified MPI inspectors?

A: You gain accurate, reliable results thanks to our ASNT Level II or III certified inspectors. Every inspection is traceable, standards-compliant, and accompanied by a detailed report and certification as per your needs, ensuring confidence in component safety.Q: Can MPI be used for large or heavy components?

A: Yes, we can inspect and handle individual components or assemblies up to 5 tons, using specialized equipment and inspection methods designed for robust and heavy-duty applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese