Remote Visual Inspection Services

Product Details:

Remote Visual Inspection Services Price And Quantity

- 1 , , Piece

Remote Visual Inspection Services Trade Information

- 100 , , Piece Per Week

- 7-10 Days

Product Description

Our Remote Visual Inspection Service forces the diamond into the material. Under stress, the indentation size is mechanically calculated by seeing through it using an optical system equipped with a CCD camera. After then, the instrument examines the data. The inspection findings are stated as the ratio of the applied load to the size of the indentation. Additionally, the LCD screen of our Remote Visual Inspection Service displays a live indentation picture, allowing for fast verification of measurement reproducibility. Our physical approach enables mobile testing of a variety of materials without the requirement to calibrate the instrument.

Other Details:

Remote Visual Inspection Services also known as RVI or RDVI, is a form of visual inspection which uses visual aids including video technology to allow an inspector to look at objects and materials from a distance because the objects are inaccessible or are in dangerous environments

RVI is also a specialty branch of nondestructive testing (NDT)

No hidden charges are applied

Service details

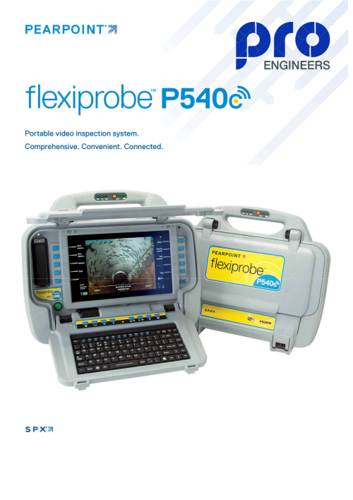

| Brand | Pro |

| Instrument Type | Borescopes |

| Inspection Method | Specific Instrumentation |

| Inspection Service For | Industrial |

| Mode Of Report | Soft Copy,Hard Copy |

| Service Location | Mumbai, Maharashtra |

| Duration | 1-3 Days |

Cutting-Edge Remote Inspection Technology

Employing advanced cameras, borescopes, and robotic crawlers, our visual inspection services deliver high-resolution results for complex and hard-to-reach areas. Our approach enhances thoroughness and ensures operational safety while minimizing equipment downtime.

Comprehensive Reporting With Rapid Turnaround

Within just 2-5 working days, certified inspection engineers provide clients with full video recordings, still images, and detailed technical reports. Data can be accessed securely via cloud or local storage based on client preference for convenience and control.

Applications Across Industrial Sectors

Designed for exporters, manufacturers, service providers, and suppliers, our services address inspection needs for internal pipelines, machinery, heat exchangers, and other industrial assets. We help meet compliance and operational efficiency requirements industry-wide.

FAQs of Remote Visual Inspection Services:

Q: How are remote visual inspections conducted for industrial equipment and pipelines?

A: Inspections are performed using high-definition cameras, borescopes, and robotic crawlers that navigate and capture detailed visuals of internal pipelines, industrial machinery, and heat exchangers. Certified engineers validate the findings to ensure accuracy and safety compliance.Q: What documentation is provided after the inspection process?

A: Each inspection delivers comprehensive documentation, including full video recordings, high-quality still images, and detailed written reports. These resources help verify equipment conditions and support maintenance, compliance, and decision-making.Q: When can I access the inspection services and reports?

A: Remote Visual Inspection Services are available 24/7 on-demand. After inspection, you can expect to receive reports and associated documentationsuch as videos and imageswithin 2 to 5 working days.Q: Where do you store and share inspection data?

A: Clients can choose between secure cloud-based storage for remote access or local storage options for privacy and data control. Both methods prioritize data protection and easy retrieval.Q: What is the resolution capability of your inspection technology?

A: Our inspection devices capture and deliver visuals in up to 1080p Full HD resolution, enabling precise evaluation of equipment conditions and identifying even minor faults.Q: How does your inspection process benefit exporters or manufacturers in India?

A: By offering quick access, certified validation, and detailed reporting, our services help exporters and manufacturers maintain compliance, reduce downtime, and optimize asset reliability in a competitive industrial landscape.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free