UCI Hardness Tester T-U2

183319 INR/Unit

Product Details:

- Display Type LCD Digital Display

- Equipment Type UCI Hardness Tester

- Color Blue

- Features Portable, Handheld, Auto calibration

- Product Type Hardness tester

- Response Time Immediate / <1 sec

- Power Supply 2pcs AA batteries

- Click to View more

X

UCI Hardness Tester T-U2 Price And Quantity

- 2 Unit

- 183319 INR/Unit

UCI Hardness Tester T-U2 Product Specifications

- UCI Hardness Tester

- LCD Digital Display

- Portable, Handheld, Auto calibration

- Blue

- Hardness tester

- Immediate / <1 sec

- Multiple test points allowed

- 3V (from 2 x AA batteries)

- 2pcs AA batteries

- 3% of reading

- USB output

- 122*65*23

- 0.1 HRC or 1 HV

- Handheld

- Metals hardness measurement

- Automatic

- -10C ~ 50C

- 20-70 HRC

- 120g

- HRC, HV, HB scales

- 90% RH

- 20-70HRC, 230-940HV, 20-1000HB

- Digital automatic

- Available as per model

- UCI Vibration ~70kHz

- Non-destructive metal testing

Product Description

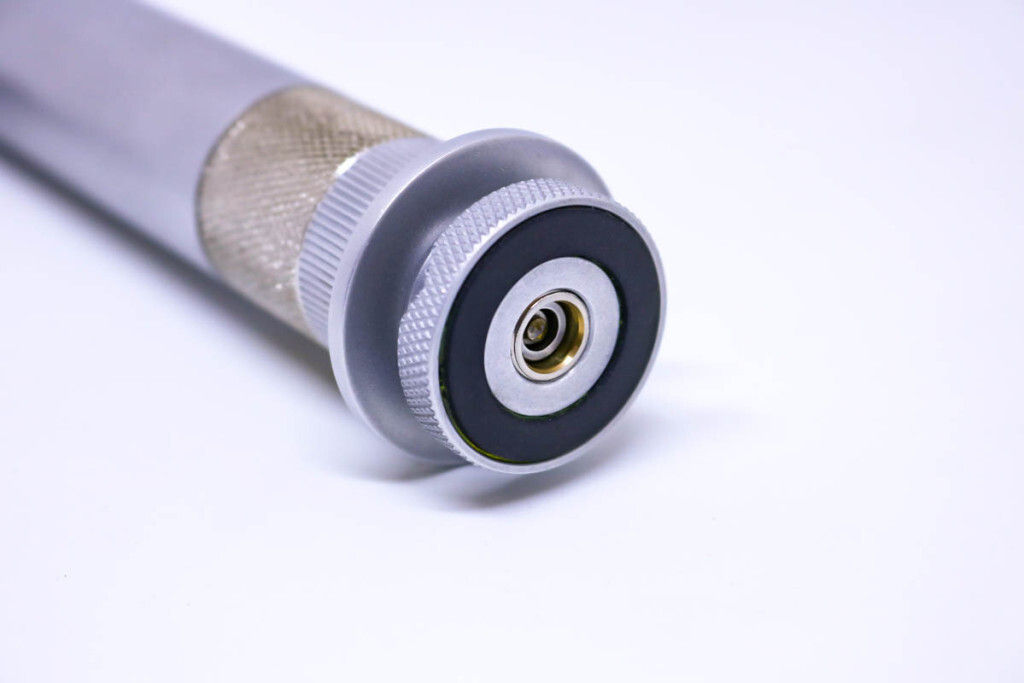

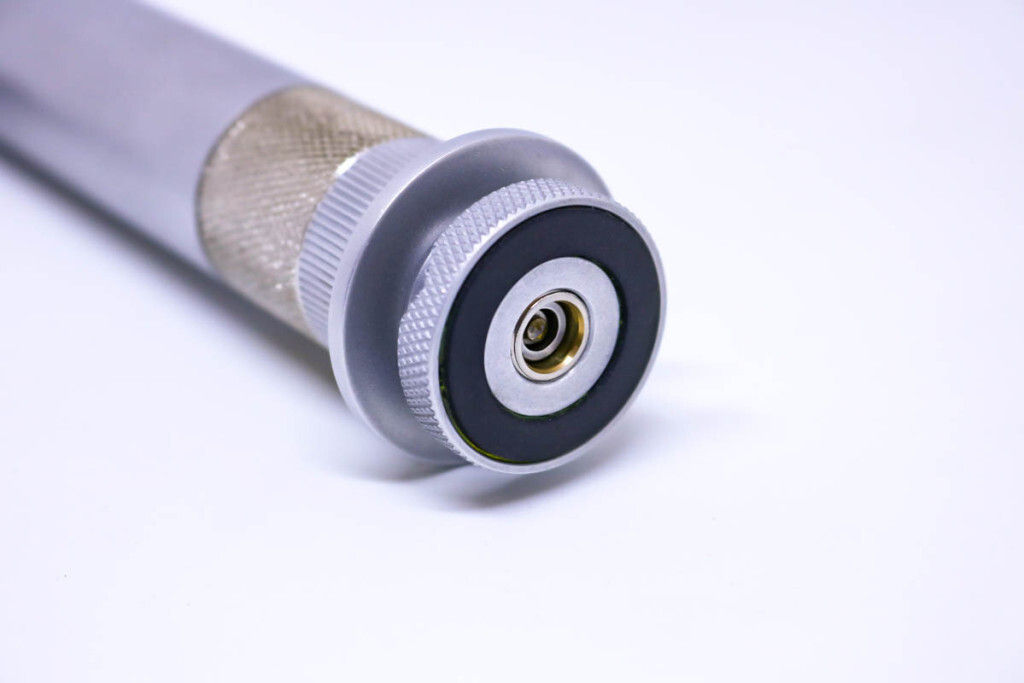

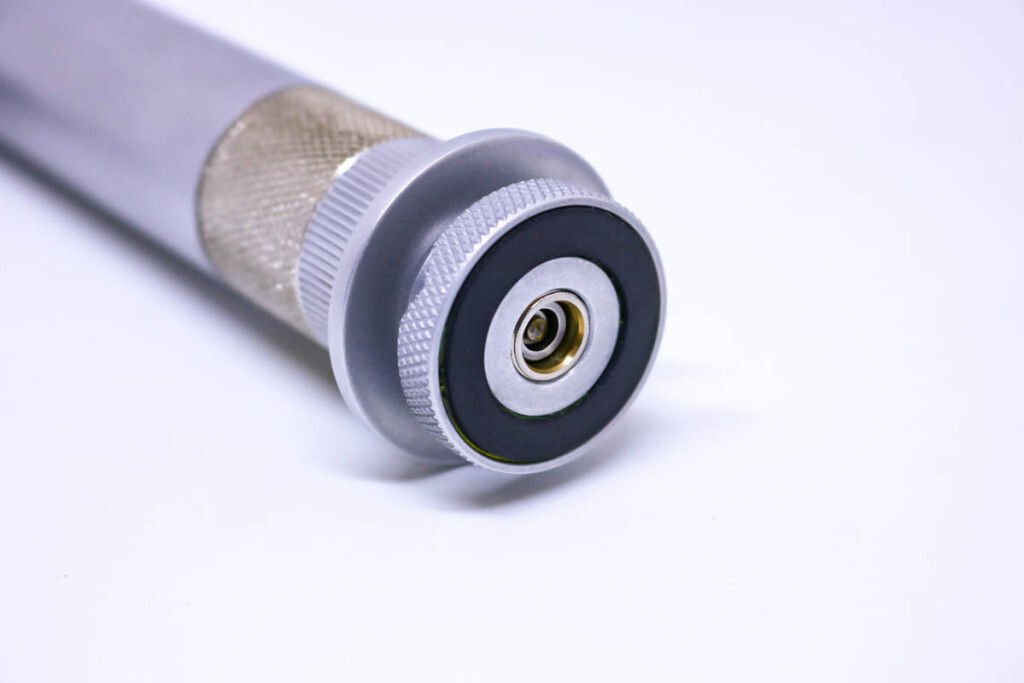

NOVOTEST T-U2 is the best price hardness tester in the world that works on UCI (Ultrasonic Contact Impedance) technology.

Unlike the Leeb hardness tester, such as the Leeb Hardness Tester NOVOTEST T-D2 and the Leeb Hardness Tester NOVOTEST T-D3, UCI hardness tester can also be used with small or thin-walled products, as well as parts of complex shape or with areas that need to be tested in hard-to-reach places.

The device with wide functionality and high reliability is UCI Hardness Tester NOVOTEST T-U2. This is a device that has been manufactured by our company for more than 10 years, and has established itself as the most optimal option in the world market for the combination of price quality.

Versatile and Accurate Hardness Measurement

The T-U2 UCI Hardness Tester is engineered for metals hardness measurement using a Vickers diamond indenter. Its digital automatic control ensures fast results, while its wide measuring range covers HRC, HV, and HB scales. Suitable for thin samples and various metals, the tester provides immediate, dependable readings, making it ideal for industrial, laboratory, and on-site inspections.

User-Friendly Design and Data Handling

With its intuitive digital LCD display and dual calibration modes, the T-U2 is easy for operators to use. Data storage is efficient with a 500-set memory and USB export capability, streamlining analysis and reporting. English is supported by default, with other languages available optionally for broader accessibility.

Portable and Reliable for Field Use

Weighing just 120g and powered by common AA batteries, the T-U2 is highly portable and suited for extended fieldwork. Its rugged design can withstand harsh environments, operating reliably within -10C to 50C and humidity up to 90% RH. Enjoy up to 20 hours of continuous use for uninterrupted performance.

FAQs of UCI Hardness Tester T-U2:

Q: How does the UCI Hardness Tester T-U2 perform hardness measurements on metals?

A: The T-U2 uses a Vickers diamond indenter with a 136 angle to create an indentation on the metal surface. The device then measures the resistance using ultrasonic contact impedance (UCI) technology, providing accurate values in HRC, HV, and HB scales, all displayed instantly on the digital LCD.Q: What are the calibration options available, and how are they performed?

A: The T-U2 supports both automatic and manual calibration. Automatic calibration uses a preset process for quick setup, while manual calibration allows for precise adjustment based on reference blocks. Both can be accessed from the user-friendly interface for reliable operation.Q: When should I use the T-U2 hardness tester?

A: Use the T-U2 whenever non-destructive, accurate hardness testing of metal samples is requiredsuch as during quality control, inspection, or maintenance. Its portability and fast response make it ideal for both laboratory and on-site field testing.Q: Where can data recorded by the T-U2 be stored and exported?

A: Test data is saved internally in the devices memory (up to 500 data sets) and can be exported via a USB output. This facilitates easy reporting, data transfer, and record keeping for analysis on external systems.Q: What is the minimum sample thickness required for accurate readings?

A: The minimum required thickness for steel samples is 0.8mm. This ensures the hardness readings are accurate and representative of the materials properties.Q: How long can the T-U2 operate continuously, and what are the power supply details?

A: Powered by two AA batteries, the T-U2 typically provides up to 20 hours of continuous operation. Its efficient design ensures it is suitable for extended periods in the field without frequent battery changes.Q: What are the main benefits of using the T-U2 UCI Hardness Tester?

A: The T-U2 offers non-destructive, immediate results on multiple hardness scales, is highly portable, requires minimal training, supports multiple calibration modes, and provides easy data management through internal storage and USB export. Its reliability and flexibility make it suitable for a wide range of metal testing scenarios.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese