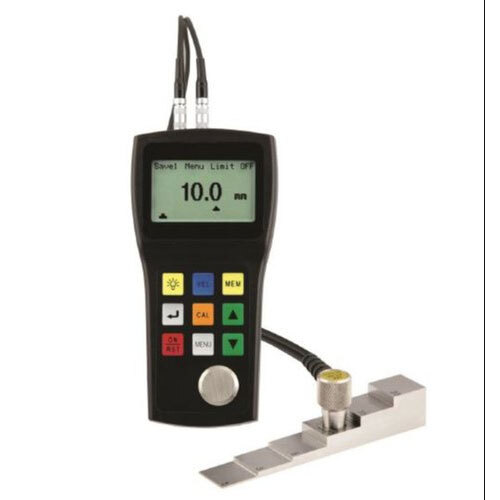

Ultrasonic Thickness Gauge PRO UT-600

Product Details:

- Display 128X64 LCD with LED back light

- Usage Industrial

- Material Plastic

- Product Type Ultrasonic Thickness Gauge PRO UT-600

- Weight 245g Grams (g)

- Color Black

- Click to View more

X

Ultrasonic Thickness Gauge PRO UT-600 Price And Quantity

- 1 Piece

Ultrasonic Thickness Gauge PRO UT-600 Product Specifications

- 245g Grams (g)

- Ultrasonic Thickness Gauge PRO UT-600

- Plastic

- Industrial

- 128X64 LCD with LED back light

- Black

Ultrasonic Thickness Gauge PRO UT-600 Trade Information

- 7-10 Days

Product Description

Specification

| Model | PRO UT-600 |

| Brand | PRO URNDT |

| Measuring Range | 0.75 TO 600mm |

| Display | 128X64 LCD with LED back light |

| Accuracyt | +-0.03mm |

| Weight | 245g |

| Battery Life | more than 50 hours (LED backlight off) |

| Battery Type | 2pcs 1.5V AA size |

| Operating Temperature | -30 TO +70C |

| Warranty | 12 MONTHS |

| Minimum Order Quantity | 1 Piece |

Product Description

STANDARD Configuration1 Main Body 1 set2 Standard Probe 5MHz,10mm1 pc3 Couplant 1 pc4 ABS Case 1 pc5 Product Certificate 1 pc6 Warranty Card 1 pc7 Manual 1 pc8 1.5V AA size 2 pcs

Precision Measurement Technology

The PRO UT-600 utilizes advanced ultrasonic technology to provide accurate and repeatable thickness measurements. This makes it an ideal tool for quality control, maintenance, and inspection of industrial parts without causing damage.

User-Friendly Display and Portability

Equipped with a high-clarity 128X64 LCD and LED backlighting, this gauge offers excellent visibility in all settings. Its 245g lightweight plastic construction means it is easy to handle and transport, even in challenging industrial environments.

FAQs of Ultrasonic Thickness Gauge PRO UT-600:

Q: How does the Ultrasonic Thickness Gauge PRO UT-600 operate?

A: The UT-600 measures material thickness by emitting ultrasonic pulses through the material and calculating the time taken for the pulses to reflect back. This non-destructive method ensures accuracy and reliability in various industrial applications.Q: What types of materials can the UT-600 measure?

A: The UT-600 is suitable for inspecting a wide range of materials such as metals, plastics, and composites, making it versatile for many industrial uses.Q: When should I use an ultrasonic thickness gauge like the PRO UT-600?

A: This device should be used when you need to accurately determine the wall thickness of components without damaging them, especially for maintenance, quality checks, or safety inspections.Q: Where is the UT-600 most commonly used?

A: The UT-600 is widely used in industries such as manufacturing, oil and gas, automotive, and construction, particularly in India where its supplied by local exporters and manufacturers.Q: What is the process for taking a measurement with the UT-600?

A: To measure, apply the probe to the surface of the clean material and read the thickness value directly from the bright LCD screen, ensuring swift and straightforward operation.Q: What are the main benefits of using the PRO UT-600 for industrial checks?

A: The UT-600 offers quick, accurate, and non-invasive thickness measurements, supporting enhanced safety, reduced downtime, and compliance with quality standards in industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free