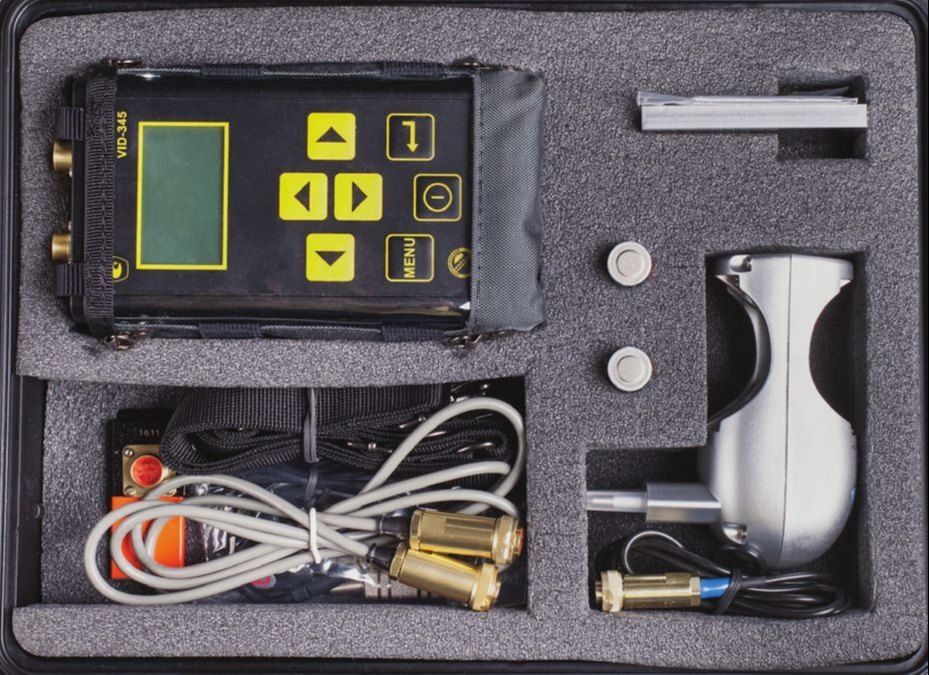

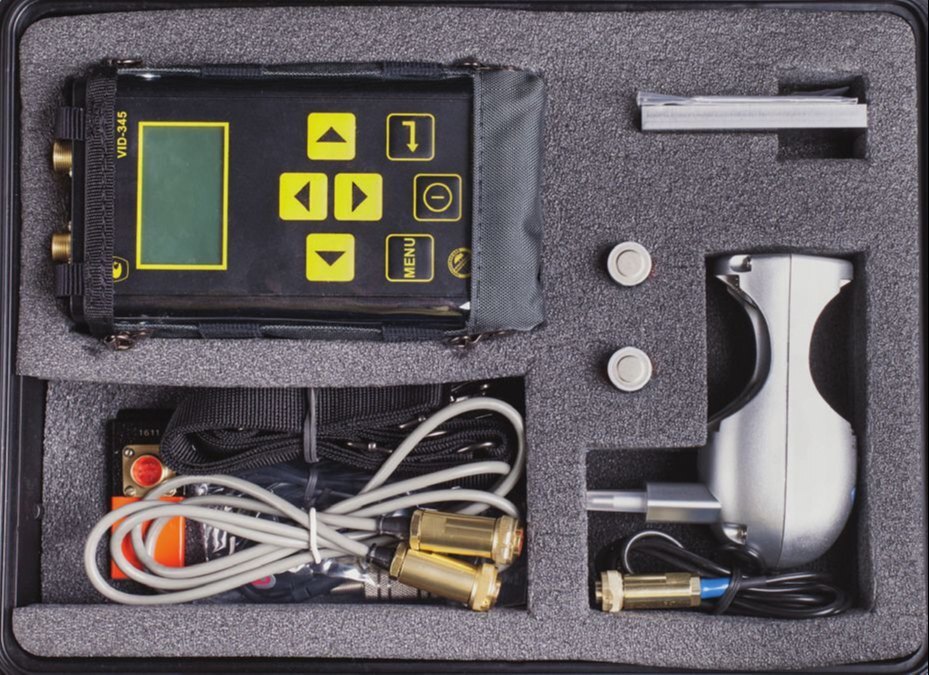

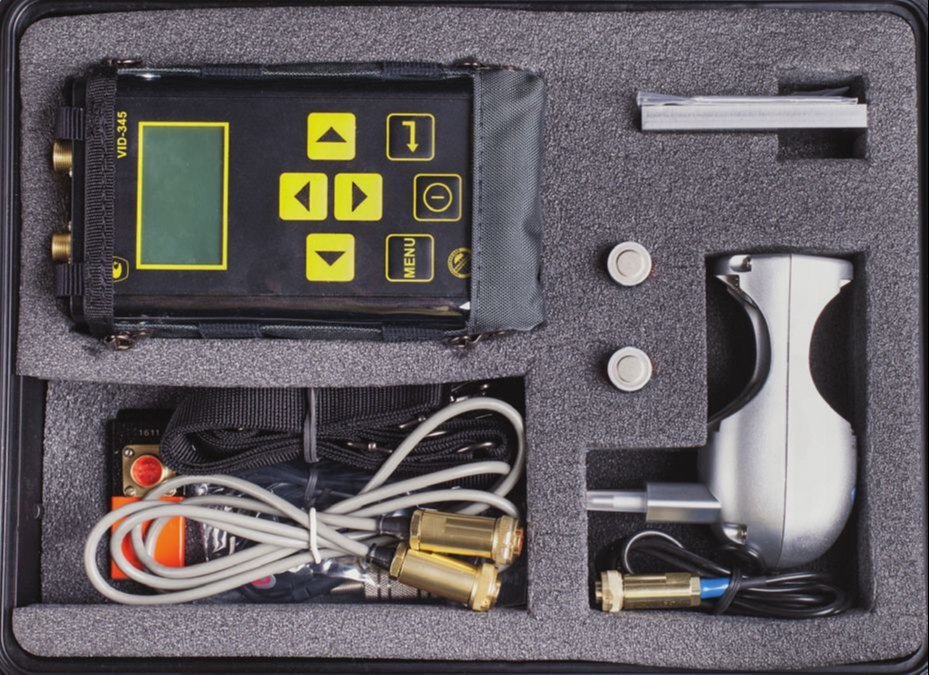

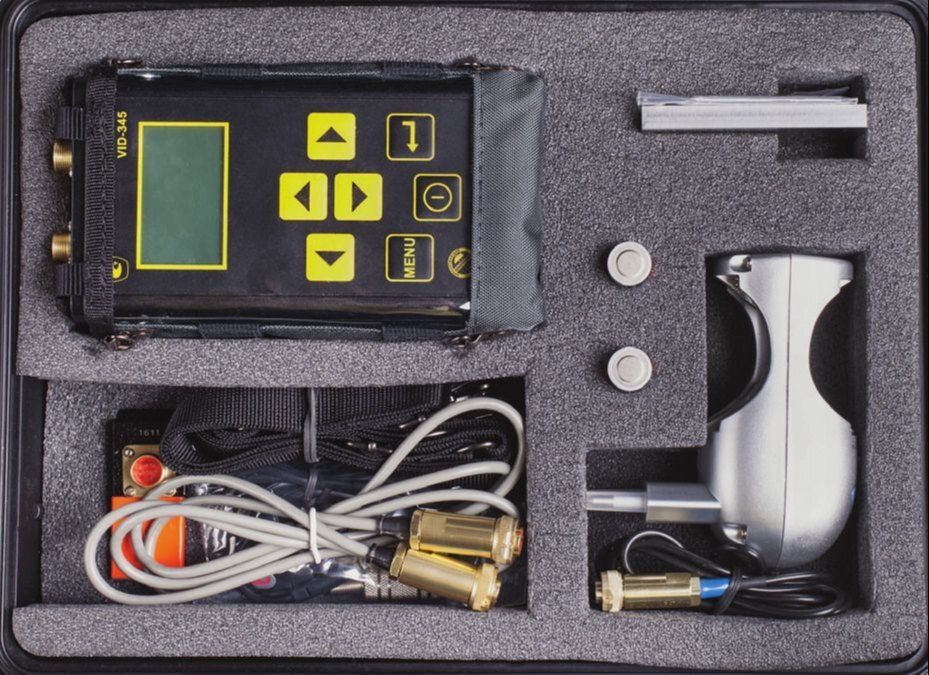

VID-345 Magnetic Eddy Current Flaw Detector

700000 INR/Piece

Product Details:

X

VID-345 Magnetic Eddy Current Flaw Detector Price And Quantity

- 1 Piece

- 700000 INR/Piece

Product Description

VID-345 Magnetic Eddy Current Flaw Detector is intended for detecting cracks and measuring their depth, detecting stress- corrosive cracks in metal ferromagnetic constructions, even under layer of corrosion and/ or protective coating.

Flaw detector enables to measure depth of corrosive damage as well as thickness of protective coating.

The device combines magnetic and eddy-current methods for flaws detection, which enables the user to control products with rough corroded surface and to measure through the layer of insulating coating of variable thickness without any additional readjustment.

Price Range : Rs 10000-300000 Per Unit

Advanced Flaw Detection Technology

The VID-345 leverages magnetic eddy current technology to provide reliable detection of surface and subsurface imperfections in conductive materials. Its wide frequency range and automatic/manual calibration guarantee high accuracy for different testing scenarios, making it suitable for a variety of industrial applications.

Effortless Operation and Portability

Designed for ease of use, the VID-345 features a tactile keypad and menu-driven interface, simplifying setup and operation. Its compact, lightweight construction (approximately 3.2 kg) and rechargeable battery support extended use in the field, ensuring effective flaw detection where mobility is essential.

Comprehensive Data Management

This flaw detector supports thorough data management with an internal memory capable of storing up to 1000 test records. Transferring test data is efficient and flexible through its USB and RS232 outputs, streamlining documentation and analysis processes for quality assurance teams.

FAQs of VID-345 Magnetic Eddy Current Flaw Detector:

Q: How does the VID-345 Magnetic Eddy Current Flaw Detector identify flaws in materials?

A: The VID-345 uses magnetic eddy current technology to detect disruptions in the electromagnetic field caused by surface or subsurface flaws, such as cracks and inclusions, within conductive materials. Its high sensitivity ensures even micro defects are identified effectively.Q: What types of probes are compatible with the VID-345?

A: The VID-345 is compatible with a variety of probe types, allowing it to be used on different conductive materials. This flexibility ensures suitability for multiple industrial inspection needs.Q: When is it recommended to use automatic versus manual calibration?

A: Automatic calibration is convenient for routine testing and ensures quick setup, while manual calibration is preferred for specialized materials or when precise adjustments are required to meet stringent accuracy standards.Q: Where can data records be stored and how is data transferred from the unit?

A: Test records are stored internally within the devices memory, capable of holding up to 1000 results. Data can be easily transferred to external devices via USB or RS232 connectivity for further analysis or documentation.Q: What is the typical operational process for using the VID-345 in the field?

A: The operator powers up the unit, selects appropriate probe and calibration mode, then scans the test material. Detected flaws trigger audible and visual alarms. Results are displayed digitally and can be stored or exported as needed.Q: How does the VID-345 benefit inspectors and quality assurance teams?

A: The VID-345 enhances inspection efficiency by providing rapid, reliable flaw detection, easy data management, and portability, leading to reduced downtime and improved material quality assurance in industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese