Automatic Coating Thickness Gauge

Product Details:

- Frequency 50 Hz 60 Hz

- Display Digital

- Outer Size 156 mm 67 mm 32 mm

- Case ABS Plastic Casing

- Measuring Range 0 - 1500 m

- Sensor Type Electromagnetic Induction Sensor

- Usage Industrial

- Click to View more

Automatic Coating Thickness Gauge Price And Quantity

- 1 Piece

- 65982 INR/Piece

Automatic Coating Thickness Gauge Product Specifications

- Industrial

- Polymer Rubber

- 2% or 2 m

- Electromagnetic Induction Sensor

- 0 - 1500 m

- Industrial

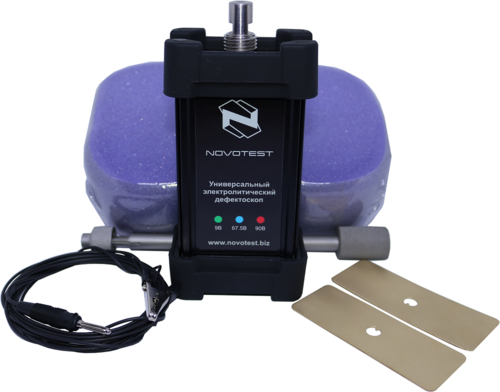

- Automatic Coating Thickness Gauge

- Stainless Steel

- ABS Plastic Casing

- 156 mm 67 mm 32 mm

- Black

- Ambient Pressure

- Digital

- 50 Hz 60 Hz

- Measurement of Paint/Coating Thickness on Metal Surfaces

Automatic Coating Thickness Gauge Trade Information

- 100 Piece Per Week

- 1 Week

- All India

Product Description

An Automatic Coating Thickness Gauge is a measuring instrument for non-destructive measurement of coating thickness on various substrates. The tool is available thanks to advanced technology, and assessments made with it are accurate and rapid. It thus helps reduce quality control procedures in the automotive, aerospace or manufacturing industries. Using eddy current or electromagnetic principles, this measuring instrument can rapidly measure coating thickness without destroying the substrate it is measuring. Its automation strengthens the reliability, eliminates human error and results in consistent output. Monitoring coating thickness The Automatic Coating Thickness Gauge is a particularly important tool for maintaining the integrity of your coated products, and for compliance with industry standards.

With enriched market experience, we have been able to offer a wide spectrum of Automatic Coating Thickness Gauge.

UCT6800 Coating Thickness Gauge Main Features:

- Two types of coating thickness including magnetic measurement principle and the principle of eddy-current principle, available to measure the thickness of the coating on non-magnetic in the magnetic metal and thickness of the non-conductive layer covering the non-magnetic metal

- High precision mode Automatically multiple measurements and data filtering method to reduce the disturbance of the measurement results

- Temperature compensation compensate for distortion caused by the measurement of temperature drift.

- Probe type automatic recognition

Main Technical Parameters:

- Sensor type F N

- Principle Introduction magnetic Eddy current

- Measuring range (m) 0~1700 0~1700 covered copper plate with chromium (0~40)

- Minimum resolution (m) 0.1 0.1

- One calibration point (um) (2% H+1) (2% H+1)

- Two puntos de calibration (m) [(1~2)%H+1] [(1~2)%H+1]

- minimum radius

- Of curvature(mm) Bulge 1.5 Bulge 3

- Minimum diameter (mm) 7 5

- Critical thickness of the base (mm) 0.5 0.3

Major operating parameters:

- Two patterns of measurement: Design and pattern continuing one

- Two patterns of work: Direct pattern and design group

- Five statistics: Mean value , maximum value, minimum value, measuring times and the standard deviation

- Calibration methods of calibration Zero point calibration and two points available to calibrate the meter can be calibrated system error of the probe using the basic calibration method

- Capable of 500 sets of measurement values: Saving function

- Elimination of function: You can delete one of the questionable data and you can also delete all the data in memory to prepare for a new measurement

- Alarm limit settings: If one of the measurement data is off limits

- Function show coupling state

- Function LED backlight, which is effective even when the light is dim

- Adjustable LCD Contrast

- Show the real-time battery

- The buzzer will prompt to make the measurement and can also disable the buzzer

- Variable waiting time, and will shut down if the weather is over

- The function of error message: Error message is displayed on the LCD or the buzzer an error message screen

- Two methods of feeding: Manual and automatic

Advanced Measurement Technology

Harnessing electromagnetic induction, this gauge delivers high-precision thickness readings on a variety of coated metal surfaces. Its digital display streamlines reading results, while dual calibration modes ensure flexibility across different applications. The sturdy stainless steel construction and ABS casing offer durability, making it suitable for harsh industrial settings.

User-Friendly and Portable Design

Weighing just 120 grams and shaped to fit comfortably in hand, this device provides effortless operation for technicians. It features an intuitive interface, quick-access buttons, and high-resolution readings. Battery power and compact size allow easy use in the field or at the job site, supporting professionals who require mobility and efficiency.

FAQs of Automatic Coating Thickness Gauge:

Q: How do I operate the Automatic Coating Thickness Gauge?

A: To operate the gauge, insert two AAA batteries, power on the device, and select the appropriate calibration modeautomatic or manualbased on your application. Place the sensor on the coated metal surface. The digital display will show the measured thickness, and readings can be stored in the internal memory.Q: What types of surfaces can this gauge measure?

A: This gauge is engineered to measure coating or paint thickness on ferrous (such as steel) and non-ferrous metals (such as aluminum), making it suitable for a wide range of industrial and manufacturing processes.Q: When should I calibrate the gauge, and what is the calibration process?

A: Calibration should be performed during the initial setup or when accuracy is critical. You may choose automatic calibration for quick adjustments, or manual calibration for more precise control. The device will provide prompts on the digital display to assist you through either process.Q: Where can this gauge be effectively used?

A: This device is ideal for use in industrial environments, including factories, workshops, and on-site inspections. It is designed to function in ambient pressure, temperatures from 0C to 40C, and relative humidity below 85%.Q: What are the benefits of using an Automatic Coating Thickness Gauge?

A: Using this gauge increases measurement accuracy (2% or 2 m), improves quality control, and streamlines reporting thanks to the internal memory capable of storing up to 1000 readings. Its fast and reliable readings help reduce rework and ensure product consistency.Q: How does the data storage feature work, and how many readings can be saved?

A: The built-in internal memory allows you to save up to 1000 thickness readings, enabling you to track, review, and export data as needed for quality verification and reporting purposes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free