Coating Thickness Gauge TPN-1

53222 INR/Piece

Product Details:

- Sensor Type Magnetic Induction

- Measuring Range 0 to 500 m

- Case Durable Plastic

- Outer Size Compact Handheld

- Display Digital LCD

- Usage Industrial

- Material Plastic/Metal Hybrid

- Click to View more

X

Coating Thickness Gauge TPN-1 Price And Quantity

- 1 Piece

- 53222 INR/Piece

Coating Thickness Gauge TPN-1 Product Specifications

- Magnetic Induction

- Industrial

- 0.05 mm %

- Coating Thickness Measurement

- Industrial Grade

- Black

- 0 to 500 m

- Plastic/Metal Hybrid

- Digital LCD

- Compact Handheld

- Rubberized Coating

- Standard

- Durable Plastic

Coating Thickness Gauge TPN-1 Trade Information

- 100 Piece Per Month

- 7 Days

Product Description

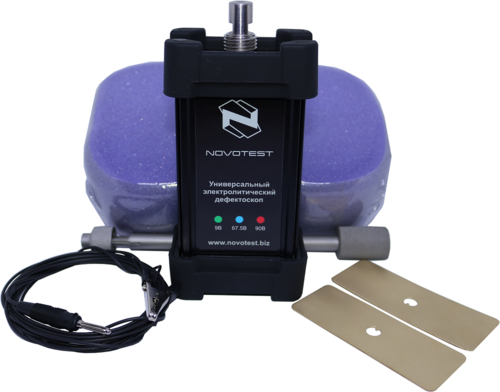

Coating Thickness Knife Tester NOVOTEST TPN-1 (Paint Inspection Gauge) is designed to measure the thickness of both single and multiple layer coatings on any grounds, both metallic and non-metallic. The operation principle is based on the local cut (notch) of the coating at the tested place of object with following thickness measurement of this coating. The thickness of coating is determined bythe width of notch, it is possiblebecause of thespecial form of cutter of the instrument. The measurement is performed by any portable measuring microscope with a suitable measuring range and discreteness.Advanced Magnetic Induction Technology

Utilizing a magnetic induction sensor, the TPN-1 Coating Thickness Gauge ensures high-precision measurements for both ferrous substrates. The digital LCD delivers real-time data, making it simple for operators to quickly assess coating thickness in various industrial environments. Its rubberized exterior enhances handling and durability even under demanding conditions.

Designed for Industrial Performance

Tailored specifically for industrial requirements, the TPN-1 offers an accuracy of 0.05 mm with a broad measuring range, supporting efficient quality inspections. Operators benefit from its ergonomic handheld size and lightweight plastic/metal hybrid construction, while the rugged plastic case assures protection during transport or fieldwork.

FAQs of Coating Thickness Gauge TPN-1:

Q: How does the TPN-1 Coating Thickness Gauge measure coating thickness?

A: The TPN-1 utilizes magnetic induction sensors to accurately determine the thickness of coatings on ferrous surfaces. The gauge converts magnetic changes into digital readings displayed on its LCD screen, ensuring precise evaluation every time.Q: What is the measuring range of the TPN-1, and what materials is it suitable for?

A: The TPN-1 offers a measuring range from 0 to 500 m, making it suitable for a wide range of industrial coatings applied to ferrous base materials. Its advanced sensor can reliably measure paints, plats, and other protective layers.Q: When should you use a coating thickness gauge like the TPN-1 in your workflow?

A: It is advisable to integrate the TPN-1 at key stages such as post-application of coatings or during quality inspections, to verify that coatings meet required specifications and to prevent issues related to insufficient or excess thickness.Q: Where can the TPN-1 Coating Thickness Gauge be effectively utilized?

A: This device is ideal for use in manufacturing sites, industrial inspection labs, automotive workshops, and any setting where coating thickness assessment on ferrous materials is critical for quality assurance.Q: What is the process for operating the TPN-1 Coating Thickness Gauge?

A: To use the gauge, simply power it on, position the sensor flat against the coated surface, and read the thickness directly from the digital LCD display. The device is designed for quick, user-friendly operation without complex setup.Q: What are the main benefits of using the TPN-1 Coating Thickness Gauge?

A: Key benefits include highly accurate measurements, ease of use, durable construction, and efficient operation for consistent quality control. Its compact portable design makes it practical for both field and laboratory use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese