Digital Hardness Tester

350638.0 INR/Piece

Product Details:

- Power Rechargeable battery

- Usage Industrial

- Size Standard

- Function Measures hardness of metals and alloys

- Accuracy +/- 1 %

- Operating Mode Portable with handheld application

- Control Mode Manual and automated operation

- Click to View more

X

Digital Hardness Tester Price And Quantity

- 350638.0 INR/Piece

- 1 Piece

Digital Hardness Tester Product Specifications

- Rechargeable battery

- +/- 1 %

- Manual and automated operation

- Measures hardness of metals and alloys

- Standard

- Conforms to ASTM E18 E140 DIN 50156 GB/T 17394

- Portable with handheld application

- Industrial

- Silver

Product Description

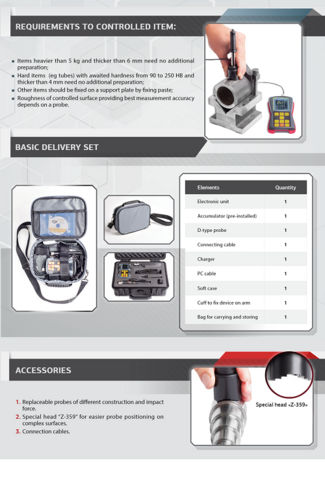

High precision hardness testerTKM359CE is intended for quickmeasuring of metal items in laboratorial,manufacturing and field conditions.Device is intended for non-destructivetesting of production quality inmetallurgy, mechanical engineering,aircraft, shipbuilding, atomic industry,oil and gas industry.Hardness tester functions by Leebmethod.Exceptional Versatility

This digital hardness tester supports both manual and automated operations, enabling users to adapt to diverse working conditions. Its robust, handheld design makes it suitable for on-site and laboratory environments alike, while maintaining high precision and user-friendly operation.

Industry-Standard Compliance

Our product strictly adheres to international and national standards, including ASTM E18, E140, DIN 50156, and GB/T 17394. This compliance ensures that your hardness measurements for metals and alloys meet global quality and reporting requirements.

FAQs of Digital Hardness Tester:

Q: How does the digital hardness tester measure the hardness of metals and alloys?

A: The tester uses advanced electronic sensors and standardized force application to determine the hardness of metals and alloys. It provides accurate readings by pressing the indenter against the material and displaying the result digitally.Q: What standards does this hardness tester conform to?

A: This product conforms to ASTM E18, ASTM E140, DIN 50156, and GB/T 17394, ensuring accurate and internationally recognized hardness measurements for a wide range of industrial applications.Q: When should I use manual versus automated operation modes?

A: Manual mode is ideal for unique or precision-critical tasks where customized control is necessary, while automated mode is suited for routine or repetitive testing to optimize efficiency and consistency.Q: Where can the digital hardness tester be used?

A: Thanks to its portable, handheld design, this tester can be used in a variety of industrial settings, including manufacturing plants, metal workshops, quality control labs, and on-site inspections.Q: What is the typical process for operating the tester?

A: Simply turn on the device, select the appropriate operation mode, place the indenter on the test material, and initiate the test. The hardness reading will appear on the digital display within seconds.Q: How does the rechargeable battery benefit industrial usage?

A: The rechargeable battery enables prolonged use without the need for frequent power supply, supporting fieldwork and continuous testing sessions with minimal downtime.Q: What are the primary benefits of choosing this hardness tester from an Indian exporter and manufacturer?

A: Customers benefit from reliable quality, adherence to global standards, exceptional after-sales support, and competitive pricing, making it a preferred option for industrial applications across India and abroad.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese