Magnetic Eddy Current Flaw Detector system

10000 INR/Unit

Product Details:

- Power 220V AC, 50Hz

- Usage Auto Testing Machine

- Function Detection and evaluation of surface and sub-surface flaws

- Accuracy 100 %

- Product Type Magnetic Eddy Current Flaw Detector

- Operating Mode Continuous / Intermittent

- Control Mode Microprocessor based

- Click to View more

X

Magnetic Eddy Current Flaw Detector system Price And Quantity

- 10000 INR/Unit

- 1 Unit

Magnetic Eddy Current Flaw Detector system Product Specifications

- 220V AC, 50Hz

- 100 %

- Detection and evaluation of surface and sub-surface flaws

- Auto Testing Machine

- Microprocessor based

- ISO 9001 Certified

- Continuous / Intermittent

- Magnetic Eddy Current Flaw Detector

- Black

Magnetic Eddy Current Flaw Detector system Trade Information

- 100 Unit Per Week

- 1 Week

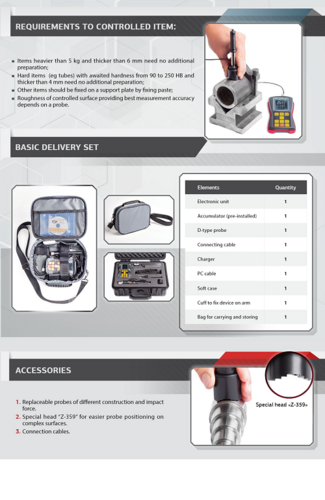

Product Description

Product details

| Detectable fracture depth range | 0.3 to 5 mm |

| Brand | Pro |

| Model Name/Number | VID 345 |

| Usage/Application | Industrial |

| Type Of Testing Machines | Eddy Current Dynamometer |

| Minimum detectable fracture length | 10 mm |

| Minimal fracture opening | 0.05 mm |

| LBH of sensor is | 25 X 25 X 60 mm |

Reliable Surface and Sub-Surface Flaw Detection

This system excels in detecting a wide range of defects in both ferro-magnetic and non-ferro-magnetic materials, ensuring thorough evaluation using advanced eddy current and magnetic flux leakage methods. With high-speed sampling and sensitive detection capabilities, it enhances quality assurance across numerous industrial applications.

User-Friendly Interface with Visual and Audio Feedback

A bright digital LED display provides clear readings, while audio and visual alarms facilitate instant operator awareness. Both manual and automatic sensitivity adjustments enable easy operation and quick adaptation to varied inspection scenarios, making the system suitable for continuous and intermittent processes.

Flexible and Expandable for Industrial Use

The detector supports interchangeable test probes and easy integration with industrial data systems via USB or RS232 interfaces. Its compliance with ISO 9001 standards and robust design ensure reliable, long-term use as an exporter, manufacturer, service provider, supplier, or trader within India and international markets.

FAQs of Magnetic Eddy Current Flaw Detector system:

Q: How does the Magnetic Eddy Current Flaw Detector identify surface and sub-surface flaws?

A: The system uses a combination of eddy current and magnetic flux leakage detection methods, which can sense changes in the electromagnetic response of materials to uncover both visible (surface) and hidden (sub-surface) defects.Q: What types of materials can be tested with this flaw detector?

A: The detector is engineered to assess both ferro-magnetic and non-ferro-magnetic materials, making it suitable for a broad range of industrial components and applications.Q: When is manual versus automatic sensitivity adjustment recommended?

A: Manual sensitivity adjustment is ideal for specific or complex inspection tasks requiring fine control, while automatic mode is useful for routine or repetitive testing to maintain consistent performance and efficiency.Q: Where can the data collected by the detector be output or stored?

A: The system is equipped with USB and RS232 interfaces, allowing seamless data transfer and integration with a variety of data recording or analysis systems, enhancing traceability and process documentation.Q: What is the process for switching test probes on this device?

A: The detector is designed with interchangeable test probes, allowing users to easily swap probes based on test requirements or material types, without the need for specialized tools.Q: How is the alarm feature beneficial during flaw detection?

A: Audio and visual alarm indications provide instant feedback upon detecting a flaw, enabling operators to quickly respond and minimize the risk of defective parts proceeding further in the production or inspection process.Q: What are the main benefits of using this system in an industrial setting?

A: Key benefits include precise flaw detection, flexible operation modes, compliance with ISO 9001 standards, high sampling rates, reliable alarm indications, and compatibility with modern data output systems, all contributing to enhanced quality control and process reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese