Eddy Current Inspection Services

Product Details:

Eddy Current Inspection Services Price And Quantity

- 1 Unit

Eddy Current Inspection Services Trade Information

- 100 Unit Per Week

- 7-10 Days

Product Description

Using the most advanced eddy current technology, our company offers Eddy Current Inspection Services, providing accurate and reliable results. For this reason, eddy current inspection plays an important role in all non-destructive testing. We have highly trained technicians with the latest equipment, providing complete examinations for every industry, from aerospace to automotive and beyond. Our services are based on a deep commitment to accuracy and efficiency, and aid in raising the level of safety and integrity for key components. Trust us for unequaled affability in Eddy Current Inspection Services, protecting your property and adhering to stringent quality controls.

Other details:

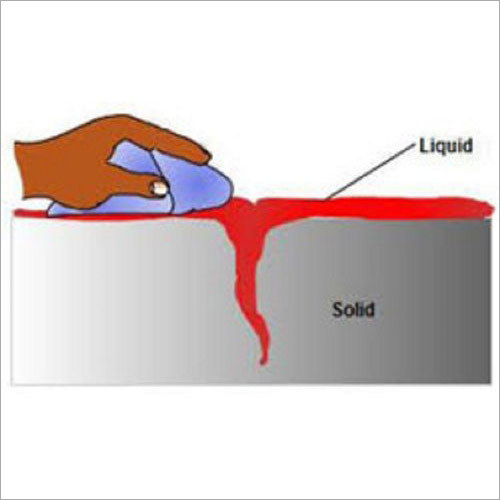

Eddy-current testing Services (also commonly seen as eddy current testing and ECT) is one of many electromagnetic testing methods used in nondestructive testing (NDT) making use of electromagnetic induction to detect and characterize surface and sub-surface flaws in conductive materials.

Services are rendered done under the stern guidance of adroit professionals.

Cost effective and timely execution of work.

Cutting-Edge Electromagnetic Induction Method

Eddy Current Inspection harnesses the power of electromagnetic induction to reveal surface and sub-surface defects in conductive materials. The advanced technique works efficiently on different types of surfaces, be they finished, raw, or coated. Leveraging a wide operating frequency range up to several MHz allows for thorough testing of diverse components.

Qualified Inspectors and Global Standards

Our personnel are certified to ASNT Level II or III, ensuring that every inspection adheres to both in-house and international calibration standards. This guarantees consistency, reliability, and full traceability of all inspection results, providing peace of mind to clients in critical industries.

Flexible Service and Comprehensive Reporting

We offer both onsite and offsite inspection services, enabling flexible scheduling to meet project demands. Our detailed reports include traceable documentation, real-time flaw detection, and data analysis, helping clients make informed decisions promptly on material integrity and safety.

FAQs of Eddy Current Inspection Services:

Q: How does Eddy Current Inspection detect flaws in materials?

A: Eddy Current Inspection employs electromagnetic induction to generate currents within conductive materials. Changes in these currents help identify surface and sub-surface anomalies such as cracks, laps, or corrosion, ensuring thorough defect assessment.Q: What types of materials and surfaces can be inspected using this service?

A: The service is suitable for inspecting conductive materials with various surface conditions, including finished, raw, or coated surfaces. Different geometries and material sizes can be accommodated based on customer requirements.Q: When is it appropriate to use Eddy Current Inspection compared to other NDT methods?

A: Eddy Current Inspection is ideal when you require rapid, high-sensitivity detection of surface or near-surface flaws, particularly in situations where the tested part remains intact. It is beneficial for high-value components or when immediate real-time results are needed.Q: Where are Eddy Current Inspection Services available?

A: We provide services across India, offering both onsite and offsite inspection, and can support export and supply requirements as a manufacturer, service provider, supplier, and trader to meet diverse client needs.Q: What is the process followed in Eddy Current Inspection?

A: Inspections begin with calibration using either in-house or international standards. Certified inspectors then scan the components with portable equipment, analyze data in real time, and generate detailed, traceable inspection reports for quality control.Q: How quickly can your team mobilize and deliver inspection results?

A: Our services feature quick mobilization to client sites, offering project-based or as-needed inspection. With real-time data analysis and rapid reporting, clients receive swift feedback to support efficient decision-making.Q: What are the key benefits of choosing your Eddy Current Inspection Services?

A: Clients gain high sensitivity flaw detection, flexible onsite/offsite service, reliable documentation, certified inspection personnel, traceable reporting, and the ability to meet diverse industry and application needs efficiently.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free