Liquid Penetrant Testing Service

Product Details:

Liquid Penetrant Testing Service Price And Quantity

- 1 Unit

Liquid Penetrant Testing Service Trade Information

- 100 Unit Per Week

- 7-10 Days

Product Description

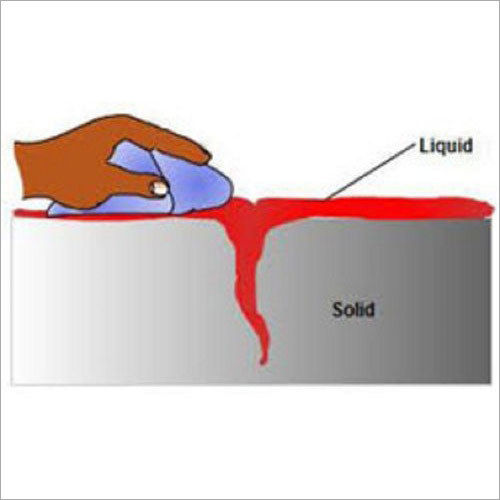

We are a Maharashtra, India firm that provides Liquid Penetrant Testing Services; our primary field of operation is non-destructive examination. This meticulous method for detection of surface flaws in various materials divulges the secret on how our technicians achieve it and helps prevent waste of critical components. The services offered by us are characterized as applying a liquid penetrant to the surface of the material. This penetrates any flaws in the material. After a predetermined dwell time, excessive penetrant will be washed away, and then a developer is applied to see if there are any indications. Equipment and expertise are not spared, and results are accurate and reliable. Help protect the safety and reliability of your components with Liquid Penetrant Testing Services.

We are renowned in the industry for providing a Liquid Penetrant Testing. Our organization is engaged in Liquid Penetrant Testing services in accordance with the clients need.

High-Precision Detection for Varied Industries

Our service caters to diverse sectors such as power plants, oil & gas, manufacturing, aerospace, and railways. Leveraging penetrants with variable sensitivity levels and fluorescent or visible dyes, we ensure precise identification of even micro surface discontinuities. Pre-treatment options like solvent and alkaline cleaning guarantee optimal test results, especially on welds, castings, and pipes.

Comprehensive Inspection, Compliance, and Documentation

Each inspection is performed by certified NDT professionals who adhere strictly to international standards, generating detailed digital or hard copy reports featuring photographic evidence. Upon completion, an official inspection and compliance certificate is issued, supporting both quality assurance and regulatory needs. Post-inspection consultation and maintenance support further enhance our customer-focused approach.

FAQs of Liquid Penetrant Testing Service:

Q: How is Liquid Penetrant Testing conducted for detecting surface defects?

A: The process involves cleaning the test surface, applying a visible dye or fluorescent penetrant, removing excess penetrant, and inspecting under UV or white light. It effectively reveals defects like cracks, seams, laps, porosity, and pinholes by highlighting surface-breaking discontinuities.Q: What penetrant sensitivity levels are offered, and how do they benefit my application?

A: We provide sensitivity levels from 1 to 4, allowing detection of a wide range of defects. Higher sensitivity penetrants are ideal for identifying fine cracks and micro discontinuities, enhancing reliability in critical components, while lower levels suit general applications.Q: When should Liquid Penetrant Testing be performed, and what industries benefit most?

A: This testing should be performed during inspection of new fabrications, post-repair assessments, or scheduled maintenance. Industries such as aerospace, power plants, oil & gas, manufacturing, and railways benefit from its ability to reveal critical surface defects in welds, castings, and forgings.Q: Where can the testing service be conducted, and is it suitable for complex geometries?

A: Our service is available both onsite and in laboratory settings. Thanks to advanced application techniques, we can inspect components with complex shapes and intricate geometries, ensuring thorough coverage and accurate results.Q: What are the environmental and safety advantages of your penetrant testing service?

A: We use eco-friendly, biodegradable penetrants that comply with international environmental standards, minimizing ecological impact and providing a safe working environment for operators and workplaces.Q: How quickly are inspection reports delivered, and what information do they include?

A: Our turnaround time is rapid, with detailed reports provided promptly in digital or hard copy format. Reports feature photographic evidence, defect identification, and comprehensive results, supporting swift decision-making and compliance certification.Q: What maintenance support and documentation are available after testing?

A: Post-inspection, clients receive a formal inspection and compliance certificate, along with expert consultation regarding maintenance actions required. Our qualified NDT professionals help interpret results and guide you on best practices for defect mitigation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese