Industrial Pipeline Endoscope

10000 INR/Unit

Product Details:

- Power Supply Electric

- Application Testing & Measurement

- Material Mild Steel

- Product Type Industrial Pipeline Endoscope

- Color Black

- Usage Measuring Tools

- Click to View more

X

Industrial Pipeline Endoscope Price And Quantity

- 1 Unit

- 10000 INR/Unit

Industrial Pipeline Endoscope Product Specifications

- Black

- Industrial Pipeline Endoscope

- Measuring Tools

- Mild Steel

- Electric

- Testing & Measurement

Industrial Pipeline Endoscope Trade Information

- 100 Unit Per Week

- 1 Week

- All India

Product Description

A pipeline endoscope, also known as a sewer inspection camera or pipeline inspection camera, is a specialized tool used for examining the interior of pipes, conduits, and other narrow passages. It typically consists of a high-resolution camera mounted on a flexible cable or rigid rod that can be inserted into the pipe. The camera captures live video footage or images of the interior of the pipeline, allowing inspectors to assess its condition, identify blockages, leaks, cracks, corrosion, or other issues.

Other Details:

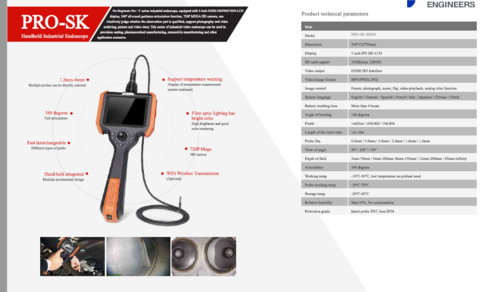

- Standard Configuration:M-55ES Endoscope 15 inch touch screen & high resolution of TFT-LCD 1

- Li Rechargeable Batteries 2 AC adapter 1 USB Cable 1 Plastic Tool Case 1 Manual

- 20 Meter Reels (30 meter, 60 meter is optional)

- Ultra-thin metal shell, weight 0.68 kg, can work in the sunshine with hood

- Screen, Resolution 800*480.

- Recording while detecting, support video playback

- Enlist operating system and USB 2.0 interface, plug & play

- Rechargeable Li-Battery lasts 7-8 hours

- Probe Diameter: 55 mm

- Probe Length: 170 mm

- Camera Direction: Front View, 2 way direction

- Visual Angle: 90/360 Rotating

- Focus: Electronic Focusing, 10 times optical zoom

- Lighting: LED light

- Camera: Color CCD

- Resolution: 480000 pixels

- Waterproof: IP60

- Best operating tube: 80 mm -2000 mm

- Wording Temperature: -10-50

Pipeline endoscopes are commonly used in various industries, including:

1. Municipalities and Utilities: Inspecting sewer lines and stormwater drains to detect clogs, damage, or structural issues that could lead to leaks or backups.

2. Construction and Engineering: Assessing the integrity of newly installed pipes or conduits before they are put into service, as well as inspecting existing infrastructure during maintenance or renovation projects.

3. Oil and Gas: Checking the condition of pipelines used for transporting oil, gas, or other fluids to ensure safety and prevent leaks or environmental damage.

4. Manufacturing: Examining the interior of pipes and machinery in manufacturing plants to monitor for wear and tear, corrosion, or other issues that could affect production efficiency or product quality.

Industrial Pipeline Endoscope Specifications:

1. Brand: Pro

2. Ultra-thin Metal Shell Weight: 0.68 kg

3. Resolution: 800x480 mm

4. Power Source: Battery

5. Model No: PRO-UR-VT-M

Pipeline Endoscope FAQ:

Q. What is a pipeline endoscope?

Ans: A pipeline endoscope, also known as a sewer inspection camera or pipeline inspection camera, is a specialized tool used for examining the interior of pipes, conduits, and other narrow passages. It typically consists of a high-resolution camera mounted on a flexible cable or rigid rod.

Q. How does a pipeline endoscope work?

Ans: A pipeline endoscope is inserted into the pipe or conduit, and the camera captures live video footage or images of the interior. This footage is transmitted to a monitor or display unit for real-time viewing. The endoscope may be equipped with LED lights for illumination and other features to enhance visibility.

Q. What are the applications of pipeline endoscopes?

Ans: Pipeline endoscopes are used in various industries, including municipalities and utilities for inspecting sewer lines, construction and engineering for assessing pipeline integrity, oil and gas for checking pipeline condition, and manufacturing for examining machinery and pipes.

Q. What are the benefits of using a pipeline endoscope?

Ans: Pipeline endoscopes allow inspectors to visually inspect the interior of pipes without the need for costly and invasive excavation or dismantling. They can identify issues such as blockages, leaks, cracks, corrosion, or other damage, enabling proactive maintenance and repairs.

Q. What features should I look for in a pipeline endoscope?

Ans: Important features to consider include camera resolution, cable length and flexibility, illumination (LED lights), recording capability, tilt and pan functions for better viewing angles, and compatibility with different pipe sizes and materials.

Q. How do I choose the right pipeline endoscope for my needs?

Ans: Consider factors such as the diameter and material of the pipes you need to inspect, the length of the inspection cable required, the level of image clarity needed for your inspections, and any specific features or accessories that may enhance usability or functionality.

Q. Are pipeline endoscopes easy to use?

Ans: Pipeline endoscopes are designed to be user-friendly, with intuitive controls and straightforward operation. However, proper training and familiarity with the equipment are essential to ensure accurate and effective inspections.

Q. Can pipeline endoscopes be used for preventive maintenance?

Ans: Yes, pipeline endoscopes are commonly used for preventive maintenance to detect potential issues before they escalate into more significant problems. Regular inspections can help prolong the lifespan of pipelines and prevent costly repairs or downtime.

Q. What safety precautions should be taken when using a pipeline endoscope?

Ans: Safety precautions may include wearing appropriate personal protective equipment (PPE), ensuring proper ventilation in confined spaces, securing the inspection area to prevent accidents, and following manufacturer guidelines for equipment use and maintenance.

Q. Can pipeline endoscope inspections be recorded or documented?

Ans: Many pipeline endoscopes are equipped with recording capabilities, allowing inspections to be documented for future reference or analysis. Recorded footage or images can also be useful for reporting findings to stakeholders or regulatory authorities.

Versatile Inspection for Industrial Applications

Engineered for pipelines, this endoscope is ideal for testing, measurement, and inspection within industrial setups. Its mild steel construction boosts longevity, while the color camera offers clear visuals. The dual power source (electric and battery) ensures operation in different environments, increasing efficiency and safety during maintenance and troubleshooting.

Precision and Reliability in Every Operation

Our industrial pipeline endoscope supports accurate, non-destructive evaluations, reducing downtime and maintenance costs. Functional for various industries, including manufacturing, construction, and utilities, it lets operators swiftly identify issues. Sourced and delivered by an experienced Indian exporter, the product stands out for its reliability and user-friendly design.

FAQs of Industrial Pipeline Endoscope:

Q: How does the industrial pipeline endoscope benefit maintenance routines?

A: The endoscope streamlines maintenance by providing clear internal visuals, enabling early detection of obstructions, corrosion, or other pipe defects. This reduces the need for invasive dismantling and minimizes downtime, ultimately saving time and resources.Q: What industries can utilize this pipeline endoscope?

A: This endoscope is suited for a wide range of industries, including manufacturing, utilities, construction, and power plants. Its testing and measurement capabilities make it essential for any application requiring internal inspection of pipelines or confined spaces.Q: When is it recommended to use the pipeline endoscope for testing?

A: Use the pipeline endoscope during routine inspections, when investigating flow problems, or after suspected damage or blockage. Early diagnostics with the endoscope can prevent major failures and ensure system reliability.Q: Where can this endoscope be deployed on-site?

A: It can be used in various on-site locations such as manufacturing plants, energy facilities, construction sites, and workshopsanywhere internal pipe inspection is needed. The devices portability and battery option enhance its usability across different settings.Q: What is the typical process involved in using the industrial pipeline endoscope?

A: To use, simply insert the camera probe into the pipeline via an access point. Navigate the endoscope to visually examine the interior through the color display, documenting results for further analysis or maintenance planning.Q: What advantages does the mild steel construction provide?

A: Mild steel ensures the endoscope remains sturdy, durable, and resistant to wear in demanding industrial conditions, contributing to a longer service life and reliable performance.Q: How do electric and battery power options improve flexibility?

A: The dual power supply allows users to operate the endoscope with mains electricity when available, or seamlessly switch to battery mode in remote or hard-to-access areas, ensuring uninterrupted inspection activities.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free