Pipeline Endoscope

Product Details:

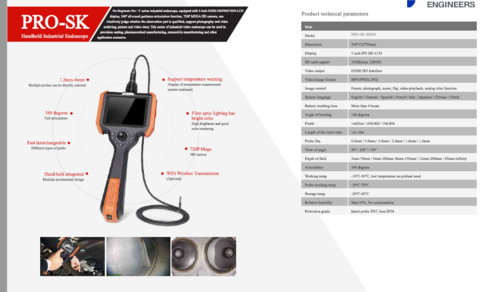

- Interface Type USB/HDMI

- Max Height 1.2 m

- Gas Pressure 0.1-0.8 MPa

- Color Black

- Measuring Range 10-200 mm

- Response Time 2 s

- Specimen Size Customizable

- Click to View more

X

Pipeline Endoscope Price And Quantity

- 1 Piece

Pipeline Endoscope Product Specifications

- 10-50 Celsius (oC)

- Flexible probe, IP67 waterproof, High-resolution camera

- 0.01 mm

- 50 Hz

- Pipeline Endoscope

- Pipeline Inspection

- Pipeline Endoscope

- LCD

- 180 mm

- 90%

- Electric

- DN50-DN300

- Semi-Automatic

- Remote/Manual

- Up to 25 mm/s

- Portable

- 90 mm

- Industrial

- High-impact ABS

- Customizable

- AC 220V, 50 Hz

- 1-4

- 0.001 mm

- 10-200 mm

- USB/HDMI

- Standard

- 1.2 m

- 7.5 kg

- 0.1-0.8 MPa

- 10-200 mm

- Black

- 2 s

Pipeline Endoscope Trade Information

- 1-7 Days

Product Description

A pipeline endoscope, also known as a pipeline inspection camera or sewer inspection camera, is a specialized tool used for inspecting the interior of pipes, conduits, and other cylindrical structures. These devices are commonly used in industries such as plumbing, construction, civil engineering, and municipal maintenance to assess the condition of pipelines without the need for costly and disruptive excavation.

Here are some key features and components of a typical pipeline endoscope:

1. Camera Head: The camera head is the most critical component of the endoscope. It usually contains a high-resolution camera equipped with LED lights to illuminate the interior of the pipeline. The camera head may be mounted on a flexible cable or rigid rod, depending on the specific design of the endoscope.

2. Flexible Cable or Rigid Rod: The camera head is connected to either a flexible cable or a rigid rod that allows it to be inserted into the pipeline. Flexible cables are more versatile and can navigate through bends and curves in the pipeline, while rigid rods provide greater stability and control in straight sections.

3. Lighting System: LED lights built into the camera head illuminate the interior of the pipeline, allowing the camera to capture clear images and videos even in dark environments.

4. Control Unit: The control unit is usually located outside the pipeline and is used to operate the endoscope. It may include features such as a display screen for real-time viewing of the inspection footage, controls for adjusting camera settings and lighting, and recording capabilities to capture images and videos for later analysis.

5. Power Source: Pipeline endoscopes are typically powered by rechargeable batteries or through a wired connection to an external power source. Battery-powered endoscopes offer greater portability and flexibility, while wired models may provide longer continuous operation times.

6. Accessories: Depending on the specific application, pipeline endoscopes may come with a variety of accessories such as interchangeable camera heads with different viewing angles, extension cables for reaching deeper into pipelines, and cleaning tools to remove debris and obstructions.

Pipeline Endoscope Applications:

1. Plumbing and Drain Inspection: Pipeline endoscopes are commonly used by plumbers to inspect residential, commercial, and industrial drainage systems. They can identify blockages, leaks, corrosion, and other issues affecting the functionality of pipes and drains without the need for extensive excavation or disruption to the property.

2. Municipal Sewer and Stormwater Inspection: Municipalities use pipeline endoscopes to inspect sewer lines, stormwater drains, and other underground infrastructure. Regular inspections help identify problems such as root intrusion, cracks, joint displacement, and sediment buildup, allowing for timely maintenance and repairs to prevent sewage backups and flooding.

3. Civil Engineering and Construction: Pipeline endoscopes are employed during the construction and maintenance of civil engineering projects such as bridges, tunnels, and underground utilities. They can assess the condition of newly installed pipes, verify proper installation, and detect any defects or damage before they compromise the integrity of the structure.

4. Industrial Pipelines: In industrial settings, pipeline endoscopes are used to inspect process pipelines, including those in chemical plants, refineries, and power plants. These inspections help ensure compliance with safety regulations, identify potential hazards such as leaks or corrosion, and prevent costly production downtime.

5. Oil and Gas Pipelines: Pipeline endoscopes are utilized in the oil and gas industry to inspect pipelines for corrosion, erosion, weld defects, and other integrity threats. Regular inspections are essential for ensuring the safe and efficient transportation of oil and gas products and for complying with regulatory requirements.

6. HVAC and Ventilation Systems: Building maintenance professionals use pipeline endoscopes to inspect HVAC ductwork, ventilation systems, and air handling units. These inspections help identify blockages, mold growth, and other issues affecting indoor air quality and HVAC system performance.

7. Aerospace and Automotive Industries: Pipeline endoscopes are also used in the aerospace and automotive industries for inspecting fuel lines, hydraulic systems, and other critical components. They can detect defects, foreign object debris (FOD), and other anomalies that could compromise the safety and reliability of aircraft and vehicles.

Comprehensive Pipeline Inspection Made Easy

The Pipeline Endoscope allows for thorough pipeline examinations with its long 20-meter cable and high-definition 1080p camera. Its 360 rotation capability ensures complete visual coverage, while adjustable LED lights provide clear images even in low-light environments. This versatile tool suits a wide range of pipe sizes and materials, enhancing accuracy and reliability during inspections.

Robust Design for Varied Environments

Built with a stainless steel probe and high-impact ABS body, this endoscope withstands harsh industrial settings. With IP67 waterproofing and an operating range of 10 to 50 Celsius, it operates reliably indoors or outdoorsa perfect fit for demanding inspection tasks. Portability and semi-automatic control further improve operator convenience and flexibility.

FAQs of Pipeline Endoscope:

Q: How does the Pipeline Endoscope capture and store inspection images and videos?

A: The device features a high-resolution 1080p HD camera and 8 adjustable LED lights, enabling clear image and video capture even in dark or challenging environments. All media files can be conveniently stored directly onto an SD card for easy access, review, and transfer.Q: What environments and conditions can this pipeline endoscope operate in effectively?

A: With an IP67 waterproof rating, operating temperature range of 1050 Celsius, and humidity tolerance up to 90%, this tool is suitable for both indoor and outdoor pipeline inspections. Its robust stainless steel probe and ABS body ensure durability across varied industrial environments.Q: When should the flexible probes 360 rotation feature be used during inspections?

A: You should use the 360 rotation function when a complete visual assessment of the pipelines interior is necessary. It allows comprehensive inspection of hard-to-reach sections, enabling detection of blockages, corrosion, or structural defects with greater accuracy.Q: Where can the Pipeline Endoscope be utilized for optimal results?

A: This endoscope is ideal for use in industrial pipeline systems within factories, plants, municipal utilities, and other facilities requiring thorough internal pipe inspections. Its design accommodates various pipe diameters (DN50DN300) and inspection depths up to 30 meters.Q: What is the process for operating and controlling the pipeline endoscope?

A: Operation is straightforward: You can remotely or manually control the probe for insertion and navigation. The device features a user-friendly LCD display, supports real-time viewing on compatible Windows, Android, or iOS devices via USB or HDMI, and allows image/video capture with minimal setup.Q: How does using this device benefit pipeline maintenance and safety?

A: By providing high-resolution, real-time visuals, this endoscope aids in early detection of problems such as leaks, blockages, or damages. This proactive approach minimizes downtime, reduces repair costs, and ensures the longevity and safety of pipeline infrastructure.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese