Liquid Penetrant Testing Services

Product Details:

- Temperature Ambient (typical service temperature: 10C - 50C)

- Interface Manual/Operator-handled

- Display Visual (dye/color developer or fluorescent under UV light)

- Material NA (Service based, applicable on ferrous and non-ferrous metals)

- Driven Type Manual/Service-based

- Size Applicable for various sizes/shapes of components

- Voltage NA (no voltage required for basic dye penetrant method)

- Click to View more

Liquid Penetrant Testing Services Price And Quantity

- 1 Unit

Liquid Penetrant Testing Services Product Specifications

- Ambient (typical service temperature: 10C - 50C)

- Applicable for various sizes/shapes of components

- NA (no voltage required for basic dye penetrant method)

- Manual/Operator-handled

- Detects surface-breaking defects as small as 1 micron

- Surface crack detection, weld inspection, casting and forging flaw identification

- Visual (dye/color developer or fluorescent under UV light)

- Not required for standard visible or fluorescent methods

- NA (Service based, applicable on ferrous and non-ferrous metals)

- Manual/Service-based

Liquid Penetrant Testing Services Trade Information

- 100 Unit Per Week

- 7-10 Days

Product Description

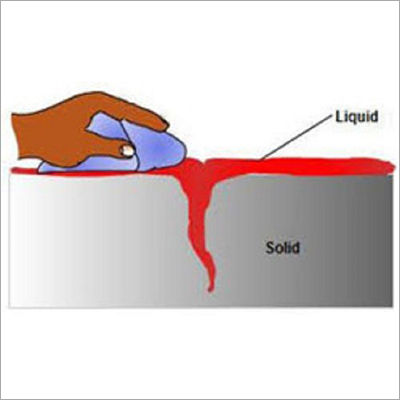

Principles: Liquid Penetrant Testing Services reveals discontinuities open to the surfaces of solid and nonporous materials. Indications of a wide spectrum of discontinuity sizes can be found regardless of the configuration of the workpiece and regardless of discontinuity orientations. Liquid Penetrant Testing Services seep into various types of minute surface openings by capillary action. The cavities of interest can very small, often invisible to the unaided eye. The ability of a given liquid to flow over a surface and enter surface cavities depends principally on the following: cleanliness of the surface, surface tension of the liquid, configuration of the cavity and size of surface opening of the cavity.

Applications: The principal industrial uses of LPT are final testing, receiving testing, in-process testing and quality control, maintenance and overhaul in the transportation industries, in plant and in testing of large components. The following are some of the typically detected discontinuities: Surface discontinuities, seams, cracks, laps, porosity and leak paths.

We are renowned in the industry for providing a Liquid Penetrant Testing. Our organization is engaged in Liquid Penetrant Testing services in accordance with the clients need.

Liquid Penetrant Testing Services Details:

| Service Mode | Offline |

| Report Aspect | Chemical Parameter |

| Application Type | Oil &Gas Piping |

| Material Type | Metal |

| Service Type | Liquid Penetrant Testing |

Reliable Surface Defect Detection

Liquid Penetrant Testing identifies minute cracks and discontinuities on the surface of metals using visible or fluorescent dyes. The method, suitable for both ferrous and non-ferrous materials, reveals flaws not easily seen with the naked eye. By following international standards, our results are trusted for quality assurance in diverse industries including manufacturing, fabrication, and structural maintenance.

Flexible Service Execution

Our services can be performed onsite at your facility or offsite in our laboratory, catering to specific project requirements. The testing process is manual and operator-handled, ensuring careful evaluation regardless of component size or geometry. By integrating defect mapping and photo documentation, we provide actionable insights for repair and maintenance.

Rapid and Safe Testing Procedures

With result times ranging from 5 to 30 minutes, liquid penetrant testing offers swift defect identification without damaging the component. The process uses either visible or fluorescent developers, requiring no power and operating at ambient temperatures. This ensures safety, minimal disruption, and efficient turnaround for urgent inspections.

FAQs of Liquid Penetrant Testing Services:

Q: How does Liquid Penetrant Testing work for surface flaw detection?

A: Liquid Penetrant Testing involves cleaning the component surface, applying a dye penetrant, removing excess penetrant, and then applying a developer that draws out dye from surface cracks. The resulting indications are inspected visually or under UV light, allowing detection of flaws as small as 1 micron on a variety of metallic materials.Q: What testing standards are followed for your Liquid Penetrant Testing services?

A: Our services strictly adhere to international standards, including ASME, ASTM E165/E1417, and ISO 3452, ensuring accurate and reliable results. These standards specify procedures, sensitivity levels, and test acceptance criteria for surface flaw identification.Q: Where can Liquid Penetrant Testing be conducted?

A: Liquid Penetrant Testing can be performed onsite at your location or offsite at our testing facility, depending on your requirements, component size, and logistics. Both options include comprehensive defect mapping and photo documentation in the final report.Q: What types of penetrants are available and when are they used?

A: We offer water-washable, solvent-removable, and post-emulsifiable penetrants. The selection depends on material type, contamination level, and required sensitivity, as outlined in the applicable testing standard. Fluorescent penetrants may be used for high sensitivity tasks and employ UV light for inspection.Q: What is the typical turnaround time for receiving test results?

A: Test results are usually available within 5 to 30 minutes after application, depending on the component size, complexity, and selected penetrant method. Immediate defect mapping and photo documentation are provided for rapid decision-making.Q: What are the main benefits of using Liquid Penetrant Testing services?

A: The main benefits include quick, accurate identification of surface defects without damaging your components, compliance with global standards, suitability for a wide range of metals and shapes, and actionable reporting for maintenance and quality assurance.Q: What are the best use cases for Liquid Penetrant Testing?

A: Liquid Penetrant Testing is recommended for surface crack detection in components, weld inspection, flaw identification in castings and forgings, and routine quality control in manufacturing, maintenance, and fabrication industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free