Ndt Testing Equipments

250000 INR/Set

Product Details:

- Measuring Range 0-100 mm

- Driven Type Manual/Electric

- Voltage 230 V

- Weight 1-5 kg

- Usage & Applications Non-Destructive Testing Industrial Use

- Size Compact/Handheld

- Display Digital/Analog

- Click to View more

X

Ndt Testing Equipments Price And Quantity

- 250000 INR/Set

- 1 Piece

Ndt Testing Equipments Product Specifications

- Battery/Direct Power

- USB/Serial

- 50 Hz Hertz (HZ)

- Metal/Plastic

- -10 to 50C

- Digital/Analog

- Compact/Handheld

- Non-Destructive Testing Industrial Use

- 1-5 kg

- Manual/Electric

- 230 V

- 0-100 mm

Ndt Testing Equipments Trade Information

- 100 Piece Per Week

- 7 Days

Product Description

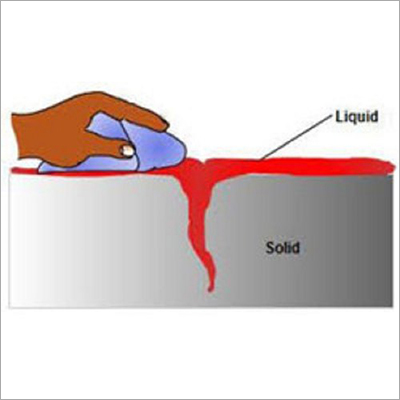

NDT Equipment checks if things are good or bad without harming them. Like a doctors checkup, it finds problems in machines or structures. It uses sound, heat, or waves to see inside without opening up. NDT keeps things safe and working well by catching issues early.Versatile Connectivity and Operation

Choose between USB or serial interfaces for seamless data transfer and analysis. Our NDT Testing Equipments offer both battery and direct power options, providing operational flexibility across different environments and applications. Manual and electric-driven types are available to suit diverse industrial needs.

Precision and Robust Build Quality

Constructed with durable metal or plastic, these devices deliver accurate measurements within a 0100 mm range. The handheld, compact design ensures easy portability without compromising precision, making them ideal for on-site and remote industrial use.

User-Friendly Display and Controls

Select from digital or analog displays for real-time, clear readings. Controls are intuitive, allowing professionals to carry out inspections efficiently, whether the device is used in a factory, field, or laboratory setting throughout India.

FAQs of Ndt Testing Equipments:

Q: How are NDT Testing Equipments typically used in industrial settings?

A: These devices are used to evaluate the integrity, composition, or structural properties of a material without causing any damage. They are employed for inspecting metal, plastic, and other components in sectors like manufacturing, construction, and maintenance.Q: What benefits do compact and handheld designs offer for NDT equipment?

A: The compact, handheld design enables operators to easily carry the device to different job sites, perform inspections in confined spaces, and conveniently operate the equipment with minimal setup, increasing both productivity and accuracy.Q: When should I use the manual versus electric-driven type?

A: Manual devices are ideal for simple, quick inspections and sites with limited power sources. Electric-driven models are recommended for more frequent or intensive testing, offering faster operation and often more consistent results.Q: Where can I use these NDT Testing Equipments?

A: Our NDT instruments can be used across various industrial environments in India, including factories, workshops, construction sites, and research facilities, due to their robust build and adaptability to diverse temperature ranges.Q: What is the process for measuring using these instruments?

A: Connect the device via USB or serial interface, choose the appropriate display type, and power it using a battery or direct connection. Place the probe on the material, and the device will provide accurate readings within the 0100 mm range.Q: How do these NDT devices ensure measurement accuracy?

A: Our instruments are engineered for high precision with reliable calibration, robust construction, and clear digital or analog displays, complying with industrial standards to deliver consistent results at a 50 Hz operation frequency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free