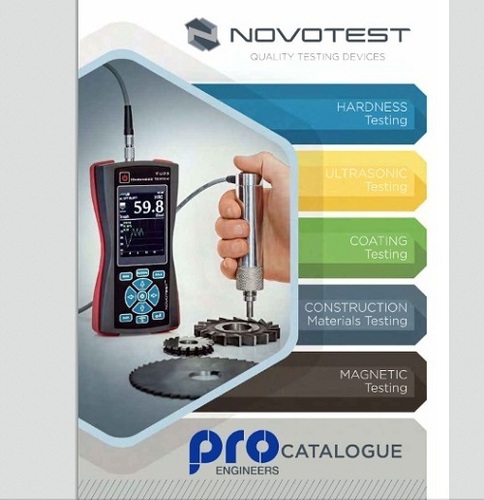

Novotest T-U3 UCI Hardness Tester

Product Details:

- Application Industrial

- Material stainless steel

- Product Type Novotest T-U3 UCI Hardness Tester

- Color Gray

- Usage manufacturing, aerospace, automotive, and metallurgy for quality control, material identification, and component testing purposes.

- Click to View more

Novotest T-U3 UCI Hardness Tester Price And Quantity

- 275258.0 INR/Unit

- 1 Unit

Novotest T-U3 UCI Hardness Tester Product Specifications

- stainless steel

- Gray

- manufacturing, aerospace, automotive, and metallurgy for quality control, material identification, and component testing purposes.

- Industrial

- Novotest T-U3 UCI Hardness Tester

Novotest T-U3 UCI Hardness Tester Trade Information

- 100 Unit Per Week

- 1 Week

Product Description

UCI hardness testing devices are commonly used in industries such as manufacturing, aerospace, automotive, and metallurgy for quality control, material identification, and component testing purposes. They offer the advantage of being portable, easy to use, and capable of providing accurate hardness measurements on-site without the need for extensive sample preparation.

- Measuring the hardness of the surface hardened layer

- Small imprint after measuring (mirror surfaces of shafts necks, blades, gear teeth, etc.)

- Wide range of hardness testing

- Various measurement modes

- Calibration of any scale in any range

- Convenience and ease for measurement

- Optimized number of buttons

- Large full color graphic display with bright back-lighting

- Calibrations stored in memory of probe

- Extended temperature range (frost, down to 40C)

- Internal memory and communication with PC

- New, intuitive menu with tips on the buttons

- Optional wireless mini printer

- Water resistant case

- Rubber protected bumper

- Has different operating modes:

- Graph the mode of building of graph

- Histogram the mode of building of histogram

- Statistics the mode of statistic

- Smart the mode of filtering of incorrect measurements

| Brand | Pro Engineers Novotest |

| Display Type | Color LCD display 320 X 240 |

| Model Number | NOVOTEST T U3 |

| Weight (kg) | Approx. 0.3kg without probe |

| Power (Hp) | DC 4.5V 3 pcs batteries AA |

| Product Type | PORTABLE |

| Memory | Limited only by the memory card up to 32Gb |

| Portable | Yes |

| Dimension (mm) | 160x75x30mm |

| Minimum Order Quantity | 1 Piece |

Advanced UCI Technology for Accurate Hardness Testing

Utilizing the Ultrasonic Contact Impedance (UCI) method, the Novotest T-U3 provides highly precise, non-destructive hardness measurements. This technology enables accurate results on stainless steel and a variety of other metals, ensuring consistent quality control across industrial applications.

Versatile Applications Across Key Industries

Engineered for robust industrial use, the Novotest T-U3 Hardness Tester is an invaluable asset in fields like manufacturing, aerospace, automotive, and metallurgy. Its adaptability makes it essential for conducting quality assurance, verifying materials, and testing critical components efficiently.

FAQs of Novotest T-U3 UCI Hardness Tester:

Q: How does the Novotest T-U3 UCI Hardness Tester work?

A: The device employs Ultrasonic Contact Impedance (UCI) technology, which measures material hardness by detecting impedance changes as a vibrating probe contacts the test surface. This allows for precise, non-destructive evaluation of stainless steel and other metals.Q: What types of industrial applications are suitable for the Novotest T-U3?

A: This hardness tester is ideal for manufacturing, aerospace, automotive, and metallurgy industries. It is frequently used for quality control, material identification, and component testing due to its adaptability and accuracy.Q: When should the Novotest T-U3 Hardness Tester be used during the production process?

A: It is most effective when used at various quality control stages: after material delivery, during in-process inspections, and for final verification of finished components to ensure that hardness requirements are consistently met.Q: Where can this device be sourced in India?

A: The Novotest T-U3 is available through authorized exporters, manufacturers, service providers, suppliers, and traders across India, making it accessible for a range of industrial users.Q: What is the process for conducting a hardness test with the Novotest T-U3?

A: Simply place the probe against the clean surface of the test material, activate the device, and receive immediate digital readings. The non-destructive method preserves sample integrity while delivering quick, reliable results.Q: What are the primary benefits of using the Novotest T-U3 in industrial settings?

A: Key advantages include its non-destructive testing capability, portability, and the ability to deliver accurate hardness measurements on-site. This efficiency helps industries maintain strict quality standards and ensure certification compliance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese