Portable Ultrasonic Flaw Detector

115000 INR/Unit

Product Details:

- Usage Industrial

- Dimension (L*W*H) 50x160x238 Millimeter (mm)

- Product Type Portable Ultrasonic Flaw Detector

- Weight 250 Grams (g)

- Color Gray

- Frequency 50-60 Hertz (HZ)

- Click to View more

X

Portable Ultrasonic Flaw Detector Price And Quantity

- 1 Unit

- 115000 INR/Unit

Portable Ultrasonic Flaw Detector Product Specifications

- Gray

- 250 Grams (g)

- Portable Ultrasonic Flaw Detector

- 50x160x238 Millimeter (mm)

- Industrial

- 50-60 Hertz (HZ)

Portable Ultrasonic Flaw Detector Trade Information

- 1000 Unit Per Day

- 1 Week

Product Description

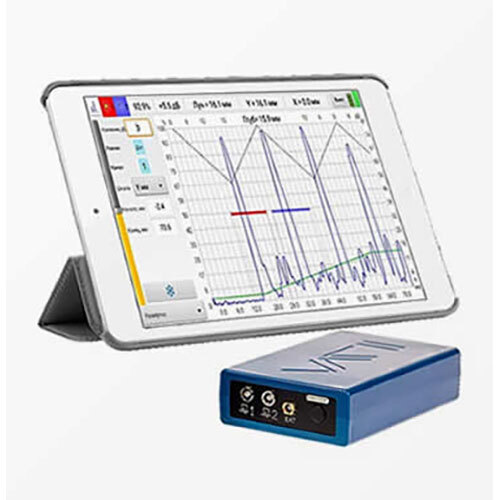

A portable ultrasonic flaw detector is a handheld device used in non-destructive testing (NDT) to detect and locate defects or discontinuities in materials such as metals, plastics, ceramics, and composites. These defects can include cracks, voids, inclusions, and other imperfections that may compromise the integrity of the material.

Portable Ultrasonic Flaw Detecting Device Specifications:

1. Weight: 250 g (Without Batteries)

2. Frequency: 50-60 Hz

3. Display Type: Digital

4. Dimension: 50x160x238 mm

5. Model Name/Number: PRO-UR-UT-UTS-270

Efficient and Reliable Flaw Detection

This ultrasonic flaw detector provides non-destructive testing for a variety of industrial components with high accuracy. Its portable design allows technicians to carry it conveniently, making it suitable for on-site inspections. This tool helps maintain quality control and ensures structural integrity without damaging the inspected part.

User-Friendly Operation

Ergonomically built, the detector features straightforward controls for hassle-free usage. Its lightweight construction minimizes user fatigue, permitting long hours of inspection. The device operates on standard 50-60 Hz power, making it adaptable to most industrial environments in India.

FAQs of Portable Ultrasonic Flaw Detector:

Q: How does the Portable Ultrasonic Flaw Detector work?

A: The detector uses high-frequency ultrasonic waves to scan materials for internal flaws or defects. When encountering a discontinuity or void inside the material, the ultrasonic signal reflects back and is interpreted by the device, revealing detailed information about the flaws location and size.Q: What materials can be inspected using this flaw detector?

A: This device is suitable for metals, alloys, plastics, and other solid industrial materials. It is commonly used to test welds, structural components, and machinery parts for hidden defects or inconsistencies.Q: When is the best time to use an ultrasonic flaw detector during production?

A: Ultrasonic flaw detection is ideally performed during or after manufacturing processes, before final product assembly or dispatch. Regular inspections can also be scheduled as part of preventive maintenance routines to ensure ongoing quality.Q: Where can I use this portable flaw detector?

A: Thanks to its compact dimensions (50x160x238 mm) and lightweight design (250 g), you can use this detector in workshops, on production lines, at construction sites, or for on-site maintenanceanywhere a quick, reliable inspection is required.Q: What is the process for operating the flaw detector?

A: Simply place the transducer probe on the surface of the material to be tested, adjust the device settings as needed, and start the scan. The results are displayed in real-time on the unit, allowing for immediate analysis and reporting.Q: What are the benefits of using this ultrasonic flaw detector in industrial settings?

A: It offers accurate, non-destructive testing, helping you identify flaws early and avoid costly failures. The portability and ease of use increase inspection efficiency, support compliance with quality standards, and enhance workplace safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free