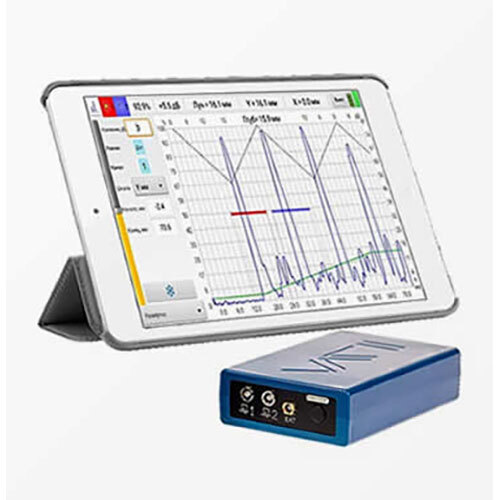

Digital Ultrasonic Flaw Detector System

115000 INR/Unit

Product Details:

- Usage Industrial

- Dimension (L*W*H) 50x160x238 Millimeter (mm)

- Product Type Digital Ultrasonic Flaw Detector System

- Weight 1 Kilograms (kg)

- Voltage 100-240 Volt (v)

- Color Black

- Frequency 50-60 Hertz (HZ)

- Click to View more

X

Digital Ultrasonic Flaw Detector System Price And Quantity

- 115000 INR/Unit

- 1 Unit

Digital Ultrasonic Flaw Detector System Product Specifications

- 50x160x238 Millimeter (mm)

- Digital Ultrasonic Flaw Detector System

- 100-240 Volt (v)

- Industrial

- Black

- 1 Kilograms (kg)

- 50-60 Hertz (HZ)

Digital Ultrasonic Flaw Detector System Trade Information

- 1000 Unit Per Day

- 1 Week

Product Description

Digital Ultrasonic Flaw Detector has been created as a cost-effective alternative to fixed hardness testing devices. In manufacturing, materials are tested to know about the characteristics of a novel material and to ensure that a sample meets a certain need. Convenience is not always possible while doing hardness tests with traditional hardness testing equipment. One popular device measures the frequency shift produced by a resonating rod fitted with a diamond tip if a particular test load is applied. The frequency change is determined and shown as a hardness value on the LCD.

Advantages:

- Automated calibration (IIW), Automated gain

- DAC, AVG, TCG, B scan, AWS, No Limited Video record,

- High-speed capture and very low noise

- high contrast viewing of the waveform from bright

- Powerful pc software and reports can be export to excel

- Automated calibration of transducer Zero Offset and/or Velocity

- Automated gain, Peak Hold and Peak Memory

- Automated display precise flaw location(Depth d, level p, distance s, amplitude, sz dB)

- Automated switch three staff gauge ((Depth d, level p, distance s)

- 300 independence setup, any criterion can be input freely, we can work in the scene without test block

- Big memory of 800 A graph

- Gate and DAC alarm, Acoustic-Optical alarm

- USB port, communication with pc is easy

- The embedded software can be online update

- Li battery, continue working time up to 12 hours

- Display freeze

- Automated echo degree

- Angles and K-value

- Lock and unlock function of system parameters

- AWS D1.1

- Dormancy and screen savers

- Electronic clock calendar

- There are 14 standards of DAC in UTS-270.

- Automated make video of test process and play Connect the USB Disk, the length of video is unlimited

- Two gates setting and alarm indication

- High-speed capture and very low noise

- DAC, AVG, TCG, B Scan, Solid plastic housing (IP65)

- Automated calculate the size of the flaw with w ide bottom type in AVG function

- 6dB DAC functions

- Provides high contrast viewing of the waveform from bright, direct sunlight to complete darkness and easy to read from all angles

- Powerful pc software and reports can be export to excel

- 2.6 Technical Parameters

- Range of scanning (mm) Range of scanning (mm):0-10000

- Adjusting step:0.1 mm(2.5 mm-99.9 mm), 1 mm(100 mm-10000 mm)

- D-delay(s) D-delay(s): -20-+3400

- Adjusting steps:0.1(-20 s-999.9 s), 1(1000 s-3400 s)

- P-delay(s) P-delay:0.0-99.99

Digital Ultrasonic Flaw Detecting Device Specifications:

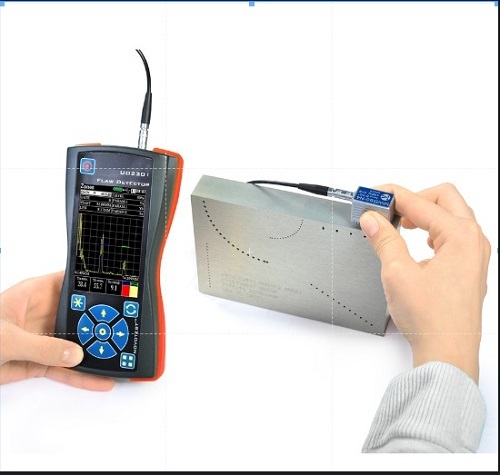

1. Model Name/Number: PRO UTS-280 Plus

2. Weight: 1Kg

3. Frequency: 50Hz-60Hz

4. Power: Input 100V - 240V

5. Dimension: 50x160x238 mm

6. Charger: 1.5A 9V Power Adapter Charger

7. Gain: 0-130 Adjusting

Advanced Flaw Detection Technology

Experience reliable and accurate flaw detection in industrial materials with the digital ultrasonic system. The device employs advanced digital processing, offering high sensitivity for the identification of internal defects. Its robust design makes it suitable for varied industrial environments.

Portability and Ease of Use

With dimensions of just 50x160x238 mm and weighing only 1 kg, this flaw detector is easy to transport and install. Its lightweight and compact build enable operators to maneuver the system in confined spaces, making it highly versatile for field inspections and factory use.

Supporting Industrial Needs Across India

As a leading exporter, manufacturer, service provider, supplier, and trader, we ensure prompt delivery and technical support throughout India. Our system is built to meet the rigorous demands of domestic and international industries, ensuring dependable operation and after-sales assistance.

FAQs of Digital Ultrasonic Flaw Detector System:

Q: How does the Digital Ultrasonic Flaw Detector System work in industrial applications?

A: The system uses ultrasonic waves to penetrate materials and identify internal flaws such as cracks or voids. Reflected sound waves are analyzed digitally, enabling precise detection and localization of defects in metals, welds, and other industrial components.Q: What are the main benefits of using this flaw detector system?

A: Users benefit from enhanced accuracy, portability due to its compact size and lightweight design, and operational safety. The system supports quick set-up and provides reliable results, reducing downtime and improving inspection workflows in industrial environments.Q: When is it recommended to use a digital ultrasonic flaw detector?

A: It is ideal for routine inspection, quality control, and verification processes in manufacturing, fabrication, and maintenance where early flaw detection can prevent failures and ensure compliance with safety standards.Q: Where can the Digital Ultrasonic Flaw Detector be utilized?

A: This system is suitable for use in various industries across India, including manufacturing plants, construction sites, engineering workshops, and maintenance facilities that require precise flaw detection.Q: What is the recommended process for using the flaw detector?

A: To use, connect the device to a 100-240 Volt power supply, calibrate it as per the material to be tested, apply couplant, and place the probe on the inspection area. Follow on-screen prompts for accurate data collection and analysis.Q: How does the frequency and voltage specification support industrial usage?

A: The 50-60 Hz frequency and wide voltage range (100-240 V) ensure compatibility with standard industrial power sources, making the system adaptable to varied operational settings without additional electrical modifications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese