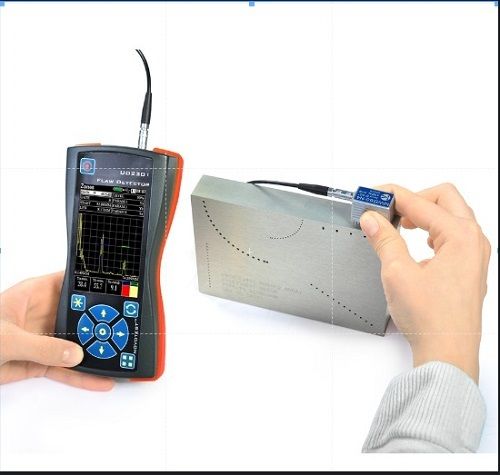

Novotest Ud2301 (mini) Ultrasonic Flaw Detector

Product Details:

- Usage Flaw Detecting

- Material Mild Steel

- Size 480x320

- Dimension (L*W*H) 80*162*38 Millimeter (mm)

- Weight 250 Grams (g)

- Voltage 5 Volt (v)

- Color Gray

- Click to View more

Novotest Ud2301 (mini) Ultrasonic Flaw Detector Price And Quantity

- 1 Piece

- 250000.00 INR/Set

Novotest Ud2301 (mini) Ultrasonic Flaw Detector Product Specifications

- 5 Volt (v)

- Gray

- 250 Grams (g)

- 80*162*38 Millimeter (mm)

- Flaw Detecting

- 480x320

- Mild Steel

Product Description

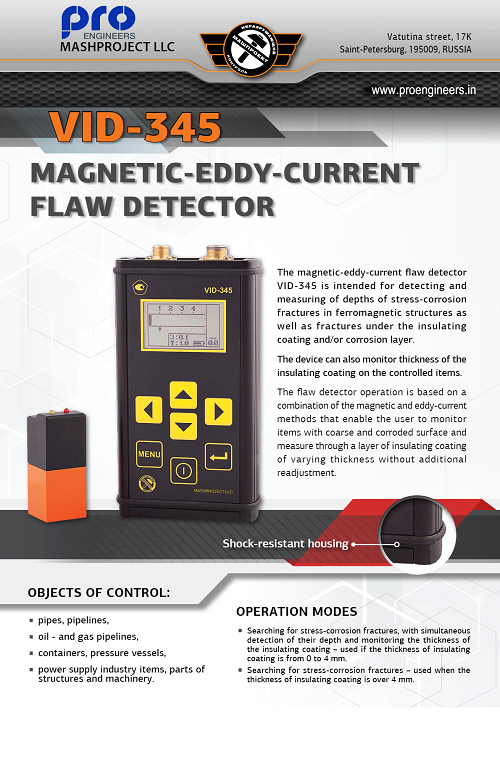

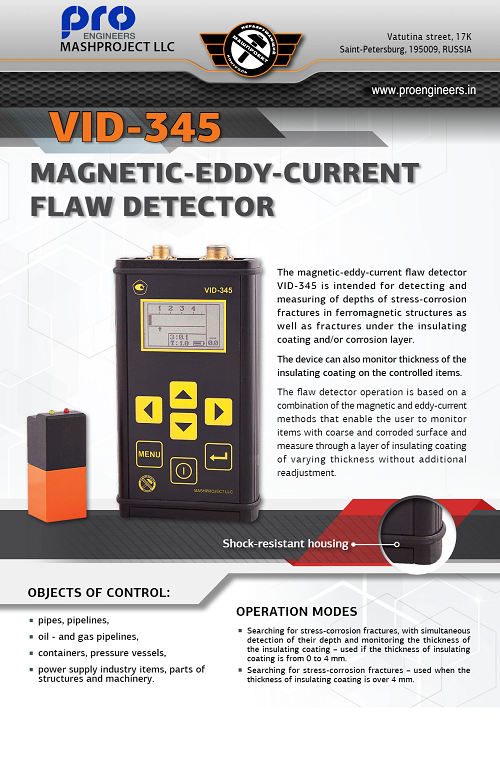

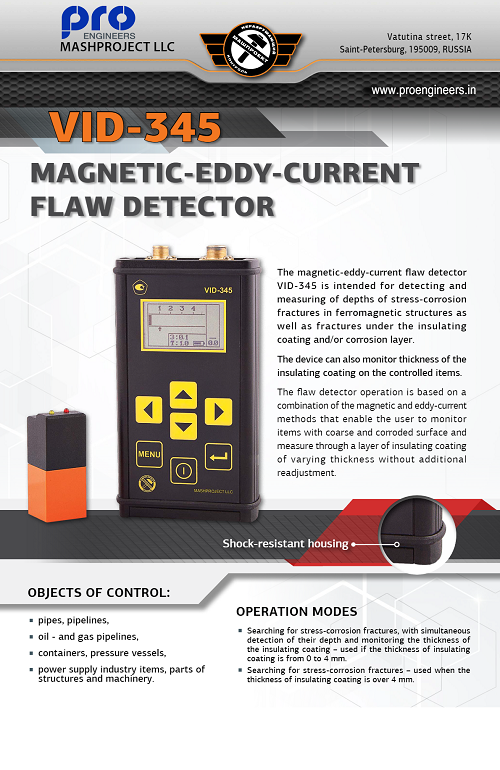

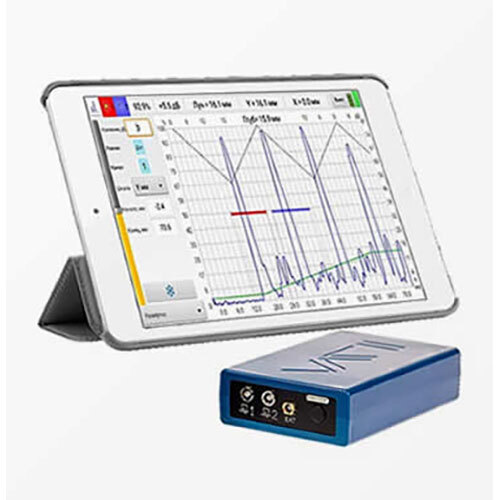

The picture on the display of the device can be rotated in 4 position, that allows to operate the device in any position, making it customisable for both: lefties and righties users, as well as positioning the Instrument in portrait and landscape orientations.

The use of the ultrasonic flaw detector:

- to test the quality of welds and base metal of products;

- to detect corrosion, cracks, delaminations and other internal defects;

- to determine coordinates and parameter estimation of defects such as discontinuity, cracks and uniformity of material in products from metal, plastic, composites and other materials;

- to measure the thickness of products.

The Flaw detector is equipped with 3 standard type AA rechargeable batteries. The device can also operate with non-rechargeable batteries of the same type. Using the batteries of standard type allows autonomous operation of the device in almost any conditions – if there is no possibility to charge batteries, it is possible to have spare batteries, or buy new batteries at any store. The Flaw detector allows user to solve a wide range of tasks – from thickness measurement of thin products to large-sized casting flaw detection.

Having sealed housing with rubber protective strips makes Ultrasonic flaw detector UD2301-mini ideal for using in workshop and field conditions with high humidity, dust, etc. The device has frost-resistant display that allows to use the device at any season and in any climatic zone of the Earth.

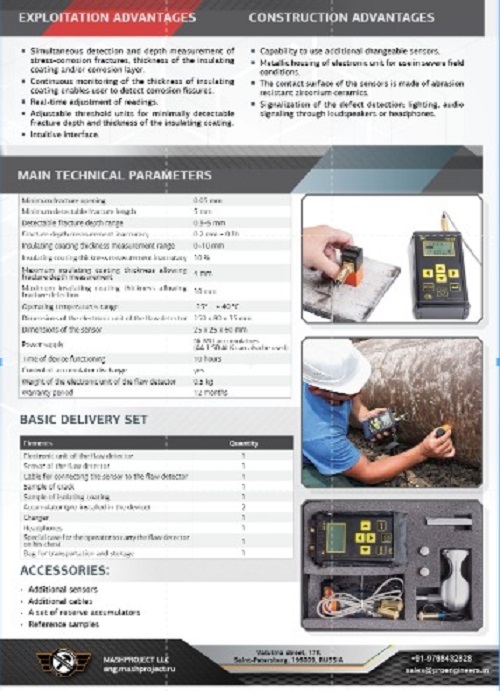

| perating frequency range | from 1 to 10,0 MHz |

| Range of measured time intervals (duration of scanning) | from 6 to 1000 µs |

| Velocity range | 1000 – 9999 m / s |

| Error of measurement of time intervals | not exceed ± 0,025 µs |

| Maximum permissible error of measurement of the amplitudes of the signals at the receiver input in the range from 0 to 110 dB | not exceed ± 0,5 dB |

| Testing gain range | 125 dB |

| Averaging over the quantity of starts | from 1 to 16 |

| Range of variation of temporal sensitivity adjustment (TVG) | 40 dB |

| Number of control points TVG | 15 |

| Duration of the excitation pulse to the load | from 0,0 to 0,5 µs |

| Amplitude of the excitation pulse to the 50 Ohm load, not less | 100, 200, 300 |

| Operating frequency range of the receiver on the level -3 dB | from 1 to 10 MHz |

| Deviation of the amplitudes of input signals in the range from 10 to 100% of the screen height not more than | 1 dB |

| Scanning | from 1 to 1000 µs |

| Delay of scanning | from 0 to 2000 µs |

| Range of measurement of time intervals | from 0 to 1000 µs |

| Setting a delay in the prism of the probe | from 0 to 15 µs |

| Automatic signaling of defects (AFS) | dual-gate |

| Setting range of AFS gates | from 0 to 2000 µs |

| Adjusting thresholds of AFS gates | from 0 to 100 % of screen height |

| Detection of signals | positive half-wave, radio mode |

| Dimensions (W*H*L) | 80*162*38 mm |

| Weight, not more | 250 g (without batteries) |

| Mean time between failures | not less than – 3000 hours |

Advanced Flaw Detection Made Simple

The Novotest UD2301 (Mini) delivers accurate flaw detection in metal structures and other materials, using advanced ultrasonic technology. Its user-friendly interface and lightweight design make it suitable for on-site inspections and routine maintenance. Ideal for industries where safety and quality assurance are critical, the device is engineered for both ease of use and precise measurement, helping professionals quickly identify material inconsistencies.

Portable and Rugged Design

Built with a compact form factor (80x162x38 mm) and a robust mild steel body, the UD2301 (Mini) is designed for durability and convenience. Weighing just 250 grams and powered by a low-voltage 5V supply, it can be easily carried to various inspection sites without added bulk, ensuring reliable operation in industrial, manufacturing, and construction environments across India.

FAQs of Novotest Ud2301 (mini) Ultrasonic Flaw Detector:

Q: How does the Novotest UD2301 (Mini) Ultrasonic Flaw Detector operate?

A: The device uses ultrasonic waves that penetrate materials, reflecting signals from internal flaws or inconsistencies. The 480x320 display provides clear readouts, allowing users to quickly analyze and identify defects within metals and other materials.Q: What materials can the Novotest UD2301 detect flaws in?

A: While primarily designed for metal inspection, the detector is versatile and suitable for use with mild steel and other common industrial materials. Its sensitive ultrasonic technology ensures reliable detection across various substrates.Q: When should the UD2301 (Mini) Ultrasonic Flaw Detector be used?

A: This device is ideal for routine maintenance, quality control, and safety inspections throughout the production process. Its portability makes it particularly useful for on-site assessments and urgent spot checks.Q: Where can the Novotest UD2301 (Mini) be utilized effectively?

A: It is effective in manufacturing plants, construction sites, fabrication workshops, and any setting where material integrity is crucial. Its compact size allows for easy use in confined or hard-to-reach spaces.Q: What is the process for using the UD2301 (Mini) Flaw Detector?

A: Setup is straightforward. Connect the probe, power the device with a 5V supply, calibrate on the material in question, and then move the probe over the area to be tested. Data is instantly visible on the display for real-time decision-making.Q: What are the benefits of choosing this ultrasonic flaw detector?

A: Key benefits include its portability, clear digital display, energy efficiency, robust construction, and suitability for a range of industrial applications. Users can expect efficient, reliable flaw detection that promotes safety and product integrity.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free