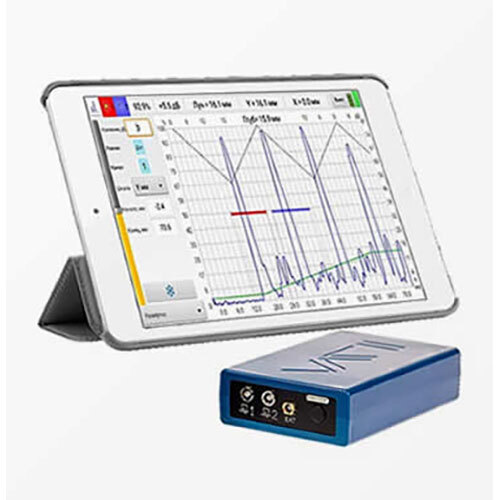

Ultrasonic Flaw Detector

Product Details:

- Dimension (L*W*H) 80x162x38 Millimeter (mm)

- Product Type Ultrasonic Flaw Detector

- Weight 250 Grams (g)

- Color Gray

- Frequency 10 Hertz (HZ)

- Temperature -5 Degree +65 Celsius (oC)

- Click to View more

Ultrasonic Flaw Detector Price And Quantity

- 115000 INR/Unit

- 1 Unit

Ultrasonic Flaw Detector Product Specifications

- 250 Grams (g)

- -5 Degree +65 Celsius (oC)

- Ultrasonic Flaw Detector

- 80x162x38 Millimeter (mm)

- 10 Hertz (HZ)

- Gray

Ultrasonic Flaw Detector Trade Information

- 1000 Unit Per Day

- 1 Week

Product Description

| Brand | PRO Engineers Novotest |

| Display Type | high resolution (320*480 pixels) |

| Weight | 250 g (without batteries) |

| Frequency | from 1 to 10,0 MHz |

| Dimension | 80x162x38 mm |

| Minimum Order Quantity | 1 Piece |

| perating frequency range | from 1 to 10,0 MHz |

| Range of measured time intervals (duration of scanning) | from 6 to 1000 s |

| Velocity range | 1000 9999 m / s |

| Error of measurement of time intervals | not exceed 0,025 s |

| Maximum permissible error of measurement of the amplitudes of the signals at the receiver input in the range from 0 to 110 dB | not exceed 0,5 dB |

| Testing gain range | 125 dB |

| Averaging over the quantity of starts | from 1 to 16 |

| Range of variation of temporal sensitivity adjustment (TVG) | 40 dB |

| Number of control points TVG | 15 |

| Duration of the excitation pulse to the load | from 0,0 to 0,5 s |

| Amplitude of the excitation pulse to the 50 Ohm load, not less | 100, 200, 300 |

| Operating frequency range of the receiver on the level -3 dB | from 1 to 10 MHz |

| Deviation of the amplitudes of input signals in the range from 10 to 100% of the screen height not more than | 1 dB |

| Scanning | from 1 to 1000 s |

| Delay of scanning | from 0 to 2000 s |

| Range of measurement of time intervals | from 0 to 1000 s |

| Setting a delay in the prism of the probe | from 0 to 15 s |

| Automatic signaling of defects (AFS) | dual-gate |

| Setting range of AFS gates | from 0 to 2000 s |

| Adjusting thresholds of AFS gates | from 0 to 100 % of screen height |

| Detection of signals | positive half-wave, radio mode |

| Dimensions (W*H*L) | 80*162*38 mm |

| Weight, not more | 250 g (without batteries) |

| Mean time between failures | not less than 3000 hours |

Ultrasonic Flaw Detector Specifications:

Ultrasonic Flaw Detector FAQ:

Q. How does an ultrasonic flaw detector work?

Q. What materials can be tested with an ultrasonic flaw detector?

Q. What types of defects can be detected with an ultrasonic flaw detector?

Q. What are the main applications of ultrasonic flaw detectors?

Q. What are the advantages of using an ultrasonic flaw detector?

Q. How do I choose the right ultrasonic flaw detector for my application?

Q. Can ultrasonic flaw detectors be used for underwater inspections?

Q. What are some common features of ultrasonic flaw detectors?

Q. How do I interpret the results obtained from an ultrasonic flaw detector?

Versatile Detection Capabilities

Our Ultrasonic Flaw Detector is engineered for versatility, enabling rapid inspection of metals, welds, and various structural components. Its sensitive ultrasound technology identifies internal defects, cracks, and discontinuities without damaging the inspected material. The device is widely utilized across sectors such as manufacturing, construction, and maintenance, ensuring the highest safety and quality standards are met.

User-Friendly, Portable Design

Designed with user comfort in mind, this detectors compact dimensions (80x162x38 mm) and lightweight (250 grams) build make it highly portable. The intuitive controls and clear display ensure quick setup and straightforward operation, even for first-time users. Its robust construction supports reliable performance under diverse industrial conditions in India.

FAQs of Ultrasonic Flaw Detector:

Q: How does the Ultrasonic Flaw Detector identify internal flaws in materials?

A: The detector uses high-frequency ultrasonic waves, which are transmitted into a material. Any internal flaws or discontinuities reflect these waves back to the device, allowing it to locate and characterize defects accurately.Q: What types of materials and industries is this flaw detector suitable for?

A: This ultrasonic flaw detector is suitable for testing metals, welds, and composite structures. It is commonly used in manufacturing, construction, aerospace, and various maintenance operations across India.Q: When is the best time to use this device during inspections?

A: The flaw detector should be used during routine maintenance schedules, after fabrication, or during quality assurance processes to verify the integrity of critical components before they are put into service.Q: Where can the Ultrasonic Flaw Detector be effectively operated?

A: Thanks to its operating temperature range of -5C to +65C, the device is suitable for use both indoors and outdoors in various industrial environments throughout India.Q: What is the process for using the Ultrasonic Flaw Detector?

A: To operate, simply power on the device and apply the ultrasonic probe to the test surface with suitable coupling gel. Adjust the settings as needed, scan the area, and interpret the readings on the color display to identify hidden flaws.Q: How can users benefit from employing this flaw detector?

A: By using this detector, industries gain the advantage of non-destructive testing, ensuring product reliability, enhancing safety, reducing maintenance costs, and minimizing operational downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese