Novotest UD3701 Ultrasonic Flaw Detector

Product Details:

- Usage Industrial

- Product Type Ultrasonic Flaw Detector

- Weight 1.7 Kilograms (kg)

- Voltage 15 Volt (v)

- Color Black

- Frequency 10-100 Hertz (HZ)

- Click to View more

Novotest UD3701 Ultrasonic Flaw Detector Price And Quantity

- 115000 INR/Unit

- 1 , , Unit

Novotest UD3701 Ultrasonic Flaw Detector Product Specifications

- 10-100 Hertz (HZ)

- Black

- Industrial

- Ultrasonic Flaw Detector

- 1.7 Kilograms (kg)

- 15 Volt (v)

Novotest UD3701 Ultrasonic Flaw Detector Trade Information

- 1000 , , Unit Per Day

- 1 Week

Product Description

| Brand | PRO Engineers Novotest |

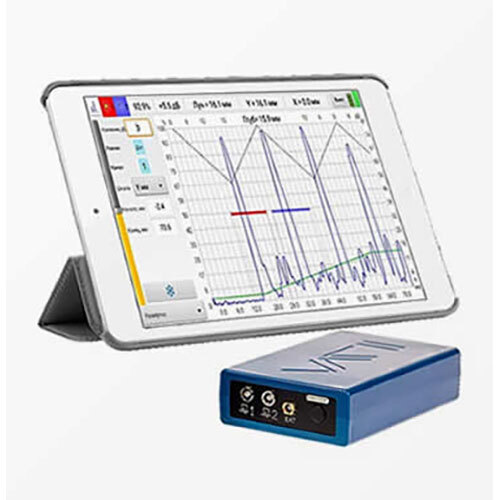

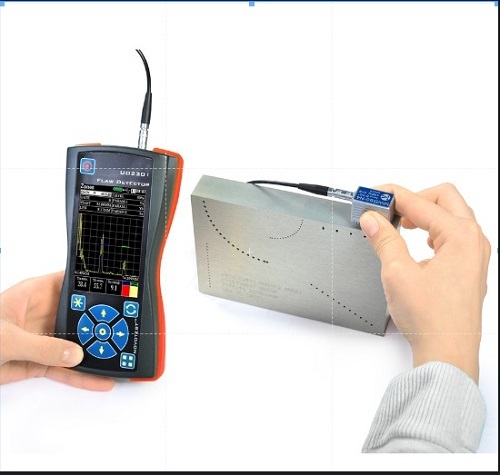

| Display Type | UD3701 has large 7 inch touch screen display and powerful, lightweight, portable and ergonomic impac |

| Power Source | power supply 220V, 50Hz AC |

| Material | MAX length of tested material up to 6000 mm (echo mode) |

| Weight (kg) | 1.7 kg with standard battery (4000 a / h) |

| Frequency (Hz) | automatically controlled from 10 to 100Hz |

| Dimension (mm) | Dimensions (H x W x L) 140 mm x 210 mm x 55 mm with standard battery (4000 a / h) 140 mm x 210 mm x |

| Voltage (V) | 15V 2A |

| Minimum Order Quantity | 1 Piece |

Product Description

- Frequency range with continuously adjustable from 0.2 to 10MHz

- Two independently controlled gate (A and B)

- Automatic or manual construction of the TCG curve (32 points)

- Two types of representations of signals: detection and radio

- Build and handling A, B scans

- Modes: envelope, freeze and display of the beam

Detailed specifications of Ultrasonic Flaw Detector NOVOTEST UD3701

Scan- min .: 0 6 s

- max .: 0 1000 s

- step 25 ns

Exposition

- from 0 s to 1000 s

- step 25 ns

MAX length of tested material

- up to 6000 mm (echo mode)

Velocity range

- 1000 9999 m/s

Exposition in the prism

- 0 100 s

- step 25 ns

Damping

- 50 Ohm

Input impedance

- 50 Ohm / 600 Ohm

Probes pulse

- RF pulse with amplitude of 100, 200 or 300V,

- With variable length from 25 to 500 ns,

- step 25 ns

Repetition frequency of SP

- automatically controlled from 10 to 100Hz

Amplifier

- Wideband 0.4-20 MHz (-6 dB)

Gain control range

- 115 dB, step 1 dB

Time control gain (TCG)

- range up to 70 dB, 12 dB / s with the construction of the curve through 16 reference points, entered by hand or by the control reflectors

Amplitude-Distance curve

- drawing through 16 points, height adjustable

Detection

- positive or negative half-wave, complete, the radio signal (at all range of scan), B-scan

Cutoff

- compensated, 0 90% of screen height

Zone control

- two independents areas, the beginning and width are change at all scan range; levels of limits are set from 0 to 100% of display height; individual logic of detection defects.

Automatic Alarm of defects

- light logic of detection defect in zone for each zone individually and sound individual logic detection defect at the zone

Time intervals measurement

- from 0 to a first signal in the zone or between

- signals in the zones to the front or to the maximum signal

Measurement of amplitude

- in dB relative to threshold level in the zone;

- in dB relative to the reference signal;

- in dB relative to the amplitude-distance curve.

Display

- Colored, TFT 320 x 240 pixels 135 x 100 mm.

Memory

- Limited of SD cards capacity

Interface

- USB, Bluetooth (optional)

Connectors of probes

- 2 Lemo

Battery

- Li-on 4-7 a / h

Battery life

- up to 10 hours with the battery 4000 a / h

- up to 24 hours with the battery 6600 a / h (optional)

External power supply

- power supply 220V, 50Hz AC

Supply voltage

- 15V 2A

Operating temperature range

- from -30 C to + 55 C

Dimensions (H x W x L)

- 140 mm x 210 mm x 55 mm with standard battery (4000 a / h)

- 140 mm x 210 mm x 85 mm with the battery 6600 a / h (optional)

Weight

- 1.7 kg with standard battery (4000 a / h)

- 2.7 kg with battery 6600 a / h (option)

Here's how it generally works:

Novotest UD3701 Ultrasonic Flaw Detector Specifications:

Advanced Ultrasonic Detection

Utilizing an impressive 10-100 Hertz frequency range, the Novotest UD3701 excels in identifying internal flaws and inconsistencies in diverse industrial materials. Its technology ensures accurate results, supporting enhanced quality assurance and safety in production processes.

Compact Yet Robust Design

Weighing only 1.7 kilograms, the UD3701 is lightweight enough for portability while maintaining exceptional durability. The sleek black finish and ergonomic structure enable comfortable usage during extended inspections, making it an asset for on-site and in-house applications.

Versatile Applications Across Industries

This ultrasonic flaw detector caters to the distinct needs of exporters, manufacturers, traders, and service providers in India. Its compatibility with a 15-volt power source enables seamless integration into existing workflows, ensuring efficient and effective flaw detection for various industrial sectors.

FAQs of Novotest UD3701 Ultrasonic Flaw Detector:

Q: How does the Novotest UD3701 Ultrasonic Flaw Detector operate?

A: The UD3701 works by emitting ultrasonic waves into the test material. Analyzing the sound waves that reflect back, it identifies internal flaws, cracks, or discontinuities without damaging the material.Q: What types of industrial applications is this flaw detector suitable for?

A: This detector is ideal for quality control in manufacturing, metal fabrication, construction, pipeline inspection, and maintenance in various industrial sectors requiring non-destructive testing.Q: When should I use ultrasonic flaw detection with the UD3701?

A: Ultrasonic flaw detection using the UD3701 is best employed during regular maintenance cycles, post-manufacturing quality checks, or whenever a detailed internal assessment of materials is needed.Q: Where can the Novotest UD3701 be utilized in India?

A: It can be used across factories, fabrication units, construction sites, and other industrial settings throughout India, thanks to its portability and compatibility with a standard 15-volt power supply.Q: What is the process of using the Novotest UD3701 for flaw detection?

A: The process involves calibrating the device, applying ultrasound couplant to the test surface, placing the probe, and scanning the area. Results are displayed in real time for analysis and documentation.Q: How does using the UD3701 benefit industrial businesses?

A: Using this instrument enables early detection of material defects, reduces the risk of equipment failure, improves safety, and helps maintain high-quality standards in production and service delivery.Q: Is this ultrasonic flaw detector easy to transport between job sites?

A: Yes, with a weight of just 1.7 kilograms and its robust design, the UD3701 is convenient to carry and suitable for both stationary and field inspections.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free