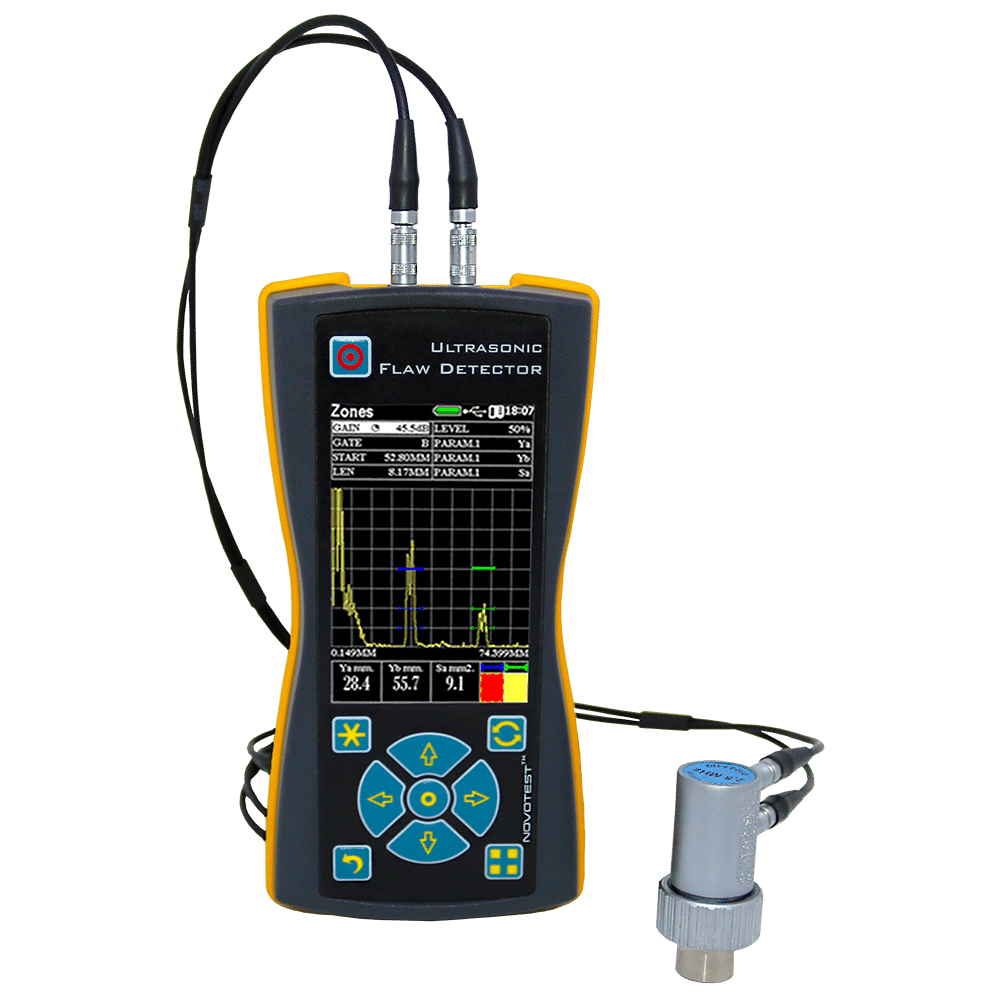

ULTRASONIC FLAW DETECTOR UD2301

256817 INR/Piece

Product Details:

- Usage INDUSTRIAL

- Dimension (L*W*H) 80*162*38 mm Millimeter (mm)

- Product Type FLOW DETECTOR

- Weight 250 g (without batteries) Grams (g)

- Color Yellow

- Frequency From 1 to 10,0 MHz Megahertz (MHZ)

- Click to View more

X

ULTRASONIC FLAW DETECTOR UD2301 Price And Quantity

- 256817 INR/Piece

- 1 Piece

ULTRASONIC FLAW DETECTOR UD2301 Product Specifications

- INDUSTRIAL

- 250 g (without batteries) Grams (g)

- FLOW DETECTOR

- From 1 to 10,0 MHz Megahertz (MHZ)

- Yellow

- 80*162*38 mm Millimeter (mm)

Product Description

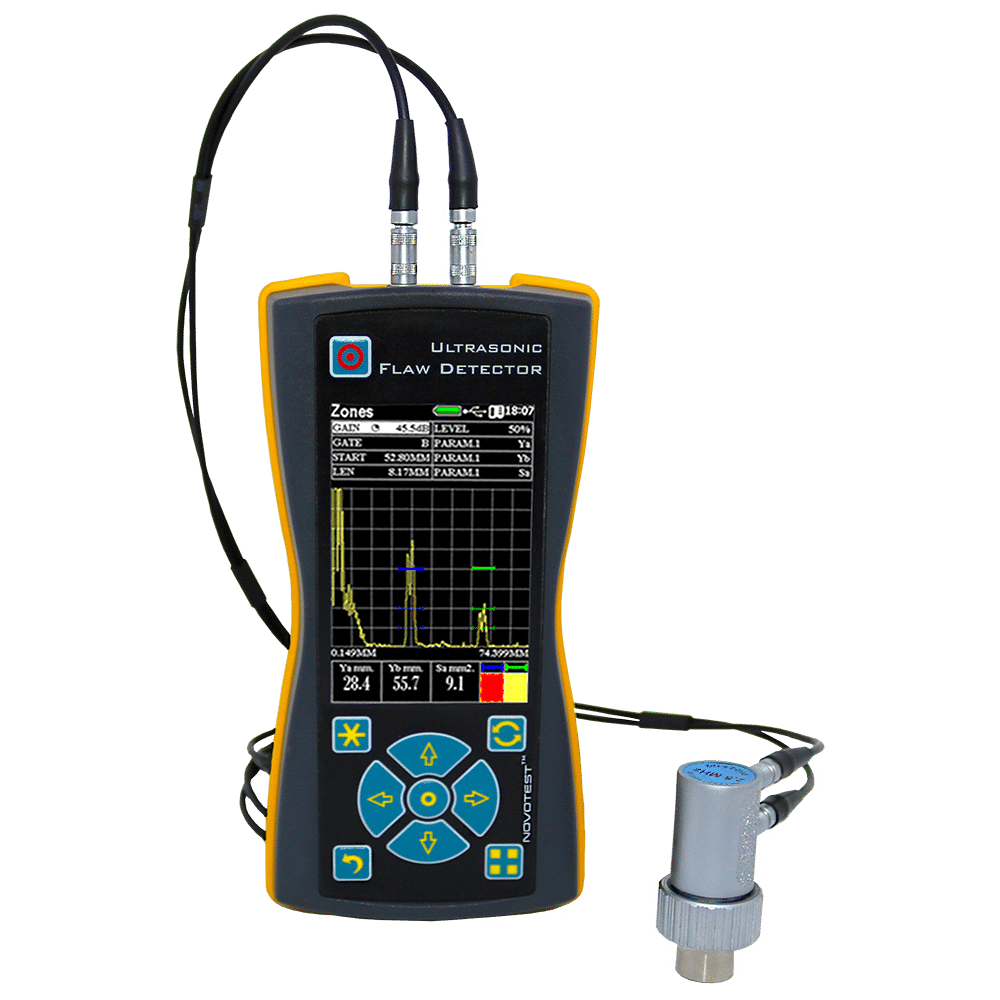

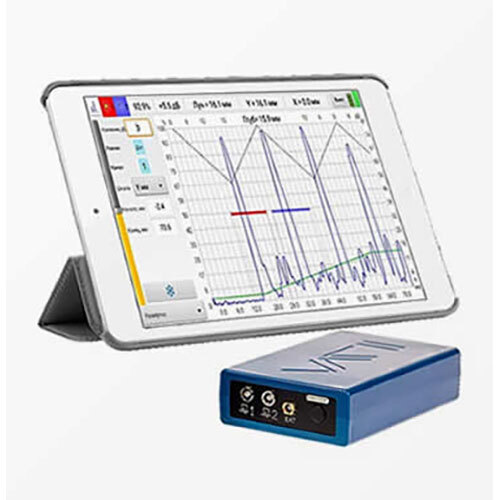

The UD2301 Ultrasonic Flaw Detectoris a powerful, ergonomic, portabledevice With all the functions of a gen.eral industrial ultrasonic flaw detec-tor- It can be used in the laboratory orworkshop and is perfect for field use.Unmatched Industrial Performance

The UD2301 offers robust performance for industrial flaw detection, leveraging ultrasonic technology to identify defects in metals, welds, and non-metallic components. Suitable for manufacturing, quality assurance, and maintenance checks, its high frequency range enhances versatility and accuracy.

Compact Design for Practical Use

Thanks to its small dimensions (80 x 162 x 38 mm) and weight of 250 g, the UD2301 is engineered for portability. Its bright yellow finish ensures visibility and safety on the factory floor, making it ideal for both field inspections and workshop usage.

FAQs of ULTRASONIC FLAW DETECTOR UD2301:

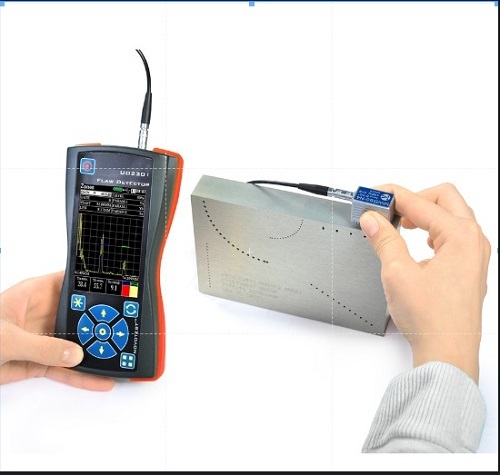

Q: How does the ULTRASONIC FLAW DETECTOR UD2301 identify flaws in materials?

A: The UD2301 uses ultrasonic pulses to penetrate the test material. By analyzing reflected sound waves, it detects inconsistencies such as cracks and voids, providing precise information on the location and size of flaws.Q: What industries can benefit from using the UD2301 flaw detector?

A: Industries such as manufacturing, construction, shipbuilding, and automotive can benefit, as the device ensures structural integrity and safety through reliable quality assessment of metals and non-metallic materials.Q: When should the UD2301 be used for flaw detection?

A: It is ideal for both routine inspections and during scheduled maintenance to detect early-stage defects, helping to prevent failures and costly downtimes in critical structures or machinery.Q: Where can the UD2301 ultrasonic flaw detector be effectively utilized?

A: Owing to its compact size, the UD2301 works well in confined or hard-to-reach spaces, making it suitable for on-site field inspections, production lines, and quality control labs.Q: What is the process of using the UD2301 for flaw detection?

A: The user applies a coupling gel to the test area, places the probe, and initiates ultrasonic waves. Variations detected in the reflected signals are analyzed on the device, pinpointing flaws within the material.Q: What are the primary benefits of choosing the UD2301 flaw detector?

A: Key benefits include portability, a wide frequency range (1 to 10 MHz) accommodating various materials, rapid setup, and accurate detection, all contributing to better quality assurance and safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese