PULSE HOLIDAY DETECTOR SPARK-I

195991 INR/Piece

Product Details:

- Product Type PULSE HOLIDAY DETECTOR SPARK-I

- Weight 1,6 kg Kilograms (kg)

- Voltage 0 40 kV Volt (v)

- Color BLACK

- Frequency 30 35 Hz Hertz (HZ)

- Click to View more

X

PULSE HOLIDAY DETECTOR SPARK-I Price And Quantity

- 1 Piece

- 195991 INR/Piece

PULSE HOLIDAY DETECTOR SPARK-I Product Specifications

- 1,6 kg Kilograms (kg)

- 30 35 Hz Hertz (HZ)

- BLACK

- PULSE HOLIDAY DETECTOR SPARK-I

- 0 40 kV Volt (v)

Product Description

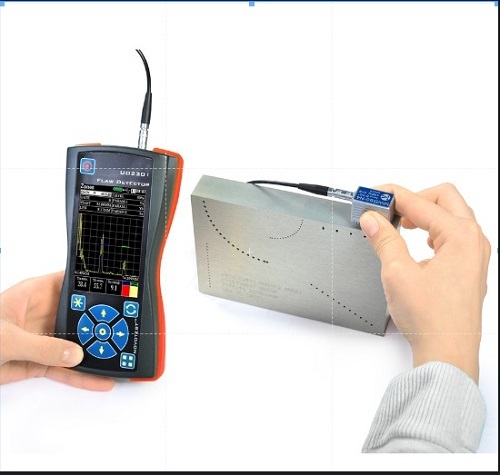

Pulse Holiday Detector NOVOTEST SPARK-1 is a device for detecting defects (thinning, microholes, cracks, etc.) in dielectric coatings on metals.The principle of operation of the device is based on the electrospark method. A probe with electrode connected to one pole of the voltage source scans the surface of the tested object directly along the coating. The second pole of the voltage source from the ground connector is connected directly to the metal structure. The electronic unit fixes the gaps by voltage between the electrode and the conductive base.

Advanced Detection Technology

The SPARK-I Holiday Detector leverages pulse technology to reliably identify defects and discontinuities in insulating coatings on conductive substrates. Its adjustable frequency and voltage ensure compatibility with a wide variety of materials and coating thicknesses, making it versatile for numerous industrial settings.

Lightweight and Durable Design

Weighing only 1.6 kg and crafted with a sturdy, black exterior, the SPARK-I is engineered for ease of use during prolonged inspections. Its compact form factor facilitates hassle-free transport and operation in diverse environments, from factory floors to field sites.

Trusted Indian Manufacturing

As a product developed and distributed by leading experts in India, the PULSE HOLIDAY DETECTOR SPARK-I exemplifies high manufacturing standards. The device is readily available for export, supply, and trading, offering reliable after-sales service and support across regions.

FAQs of PULSE HOLIDAY DETECTOR SPARK-I:

Q: How is the PULSE HOLIDAY DETECTOR SPARK-I used for coating inspection?

A: The SPARK-I is employed to detect pinholes and discontinuities in protective coatings on metal surfaces. Pass the detectors probe over the coated surface; any defect will allow a pulse signal, indicating the location of the flaw.Q: What is the typical process for operating the SPARK-I?

A: To operate, set the required voltage depending on the coating thickness (040 kV range), select the proper frequency (3035 Hz), then slowly guide the detector over the surface. A signal will alert you to any coating defect or holiday detected.Q: When is it ideal to use the SPARK-I Holiday Detector?

A: The SPARK-I is best used during and after the application of protective coatings to verify their integrity before the structure or component is put into service. Routine inspections can also be performed as part of maintenance procedures.Q: Where can the SPARK-I Holiday Detector be applied?

A: The detector is suitable for industrial sites such as pipeline installations, tanks, bridges, and any environment where protective coatings are applied to conductive materials and quality assurance is essential.Q: What are the benefits of using the SPARK-I for holiday detection?

A: By employing the SPARK-I, industries minimize the risk of corrosion and extend the lifespan of coated assets. Its accurate and rapid detection ensures quality assurance and reduces the need for costly repairs.Q: How flexible is the SPARK-I for export and supply purposes?

A: As an exporter, manufacturer, service provider, supplier, and trader based in India, the SPARK-I is widely available for supply both domestically and internationally, with robust after-sales support and service options.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free