Time-Of-Flight Diffraction Ultrasonic Testing Services

Product Details:

X

Product Description

Time-Of-Flight Diffraction Ultrasonic Testing Services details

With an objective to fulfill the diversified needs of the customers, we also provide services for Time-of-flight diffraction Ultrasonic Testing (TOFD). Offered service is rendered by experienced professional.

| Type of Testing Machines | Compression Testing Machine |

| Display Type | Digital |

| Temperature | -5 Degree +65 Degree |

| Material | MS |

| Resolution | 0.01 mm |

| Frequency | 50 Hz |

| Usage/Application | Industrial |

Advanced Crack Detection Technology

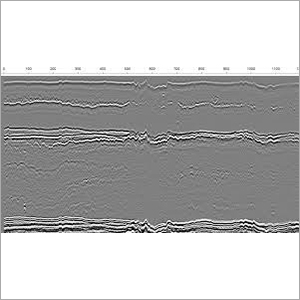

Leveraging the TOFD (Time-Of-Flight Diffraction) technique, our ultrasonic testing services accurately identify and size flaws such as cracks and inclusions in welds and base materials. This technology ensures exceptionally high detection sensitivity for critical applications.

Comprehensive Weld and Corrosion Assessment

Our services cover weld inspection, corrosion mapping, and defect sizing, supporting the integrity and longevity of industrial assets. Detailed assessments help prevent unexpected failures and ensure compliance with stringent standards like ASME, ASTM, EN, and ISO.

Certified Experts and Automated Reporting

All inspections are performed by ASNT Level II/III certified personnel, assuring professional expertise. We deliver thorough digital reports with interpretive analyses, supported by automated data storage and backup for maximum security and traceability.

FAQs of Time-Of-Flight Diffraction Ultrasonic Testing Services:

Q: How does TOFD Ultrasonic Testing detect flaws in materials?

A: TOFD Ultrasonic Testing uses ultrasonic waves and the principle of time-of-flight diffraction to detect and size cracks or defects. By monitoring how these waves interact with flaws, the method delivers precise and reliable results, often surpassing traditional methods in accuracy.Q: What types of materials and thicknesses are suitable for TOFD inspection?

A: TOFD is ideally compatible with carbon steel, alloy steel, and stainless steel materials with thicknesses of 6 mm and above, making it suitable for a wide range of industrial components and welded structures.Q: When is TOFD testing recommended for industrial applications?

A: TOFD testing is recommended during critical weld inspections, corrosion mapping, or when precise defect sizing is required. It is particularly valuable for new constructions, periodic maintenance, and after repairs on structural components.Q: Where are your TOFD Ultrasonic Testing Services available?

A: Our TOFD testing services are available throughout India. We offer onsite, offline evaluations in any region, providing reliable testing wherever your project may be located.Q: What is the process of performing a TOFD inspection?

A: The inspection involves setting up calibrated ultrasonic equipment, scanning the test area, and acquiring detailed data, all conducted by certified personnel. The collected data is analyzed, and a comprehensive digital report with flaw interpretation is provided to the client.Q: How is the data from TOFD inspections managed and reported?

A: All data is automatically stored and backed up to ensure security and traceability. Clients receive a detailed digital report with clear flaw interpretations, supporting informed decision-making.Q: What are the benefits of using your TOFD Ultrasonic Testing Services?

A: Our services offer high detection accuracy, fast and efficient inspections, compliance with global standards, expert personnel, detailed digital reporting, and comprehensive data managementensuring dependable results for your inspection needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free